Example Systems

Copyright Notice

© 2012 All Rights Reserved

Daxesoft Ltd.

Distribution Limited to Authorized Persons Only.

Trade Secret Notice

The PipeFlow.com, PipeFlow.co.uk and Daxesoft Ltd. name and logo and all related product and service names, design marks, logos, and slogans are either trademarks or registered trademarks of Daxesoft Ltd. All other product names and trademarks contained herein are the trademarks of their respective owners.

Printed in the United Kingdom - November 2012

Information in this document is subject to change without notice. The software described in this document is furnished under a license agreement. The software may be used only in accordance with the terms of the license agreement. It is against the law to copy the software on any medium except as specifically allowed in the license agreement. No part of this document may be reproduced or transmitted in any form or by any means electronic or mechanical, including photocopying, recording, or information recording and retrieval systems, for any purpose without the express written permission of Daxesoft Ltd.

Table of Contents

Table of Contents

Common 03 - Pipe Fittings & Valves

Common 05 - Enlargements & Contractions

Common 07 - Cv or Kv Control Valve Coefficients

Common 08 - Heat Exchangers, Cooling Coils, Chillers, Fan Coils

Common 09 - Sprinklers / Spray Nozzles

Common 10 - Flow Control Valves (FCVs)

Common 11 - Pressure Reducing Valves (PRVs)

Common 12 - Back Pressure Valves (BPVs)

Common 13 - Closed Loop Systems

General 02 - Tank to Joint Outflow

General 03 - Gravity Flow to 3 Outlet Points

General 04 - Fixed Flow Pumping to 3 Tanks

General 05 - Fixed Head Pumping to 3 Tanks

General 06 - Fixed Speed Pump with Performance Curve

General 07 - Pressurised Pumping Stations

General 09 - Energy Recovery with Turbine

General 10 - Top Up Tanks - Closed Loop Pressurized Recirculation System

General 11 - Replacement Pipe Size

General 12 - Step By Step (User Created Example)

General 13 - Pressure Reducing Valves

General 14 - Back Pressure Valves

General 15 - Fire Hydrant Supply

Isometric 01 - Chilled Water Cooling

Isometric 02 - Chilled Water Campus Cooling

Isometric 04 - AHUs Single Pump

Isometric 05 - Water Distribution System

Isometric 06 - Water Circulation System

Isometric 07 - Fire Protection Sprinklers

Isometric 08 - Fire Protection Water Mist

Gases 01 - Compressed Air Distribution

Gases 02 - Compressed Air Zoned

Table of Figures

Figure 1 Common 01 - Tanks

Figure 2 Common 02 - Flow Demands

Figure 3 Common 03 - Pipe Fittings & Valves

Figure 4 Common 04 - Tee Fittings

Figure 5 Common 05 - Enlargements & Contractions

Figure 6 Common 06 - Pump Types

Figure 7 Common 07 - Cv or Kv Control Valve Coefficients

Figure 8 Common 08 - Heat Exchangers, Cooling Coils, Chillers, Fan Coils

Figure 9 Common 09 - Sprinklers / Spray Nozzles

Figure 10 Common 10 - Flow Control Valves

Figure 11 Common 11 - Pressure Reducing Valves

Figure 12 Common 12 - Back Pressure Valves

Figure 13 Common 13 - Closed Loop systems

Figure 14 Common 14 - Fluid Zones

Figure 16 General 01 - Three Reservoirs

Figure 17 General 02 - Tank to Joint Outflow

Figure 18 General 03 - Gravity Flow to 3 Outlet Points

Figure 19 General 04 - Fixed Flow Pumping to 3 Tanks

Figure 20 General 05 - Fixed Head Pumping to 3 Tanks

Figure 21 General 06 - Fixed Speed Pump with Performance Curve

Figure 22 General 07 - Pressurised Pumping Stations

Figure 23 General 08 - Reverse Pipe

Figure 24 General 09 - Energy Recovery with Turbine

Figure 25 General 10 - Top Up Tanks - Close Loop Pressurized System

Figure 26 General 11 - Replacement Pipe Size

Figure 27 General 12 - Step By Step

Figure 28 General 13 - Pressure Reducing Valves

Figure 29 General 14 - Back Pressure Valves

Figure 30 General 15 - Fire Hydrant Supply

Figure 31 Isometric 01 - Chilled Water Cooling

Figure 32 Isometric 02 - Chilled Water Campus Cooling

Figure 33 Isometric 03 - HVAC 3 Pumps

Figure 34 Isometric 04 - AHUs Single Pump

Figure 35 Isometric 05 - Water Distribution System

Figure 36 Isometric 06 - Water Circulation System

Figure 37 Isometric 07 - Fire Protection Sprinklers

Figure 38 Isometric 08 - Fire Protection Water Mist

Figure 39 Gases 01 - Compressed Air Distribution

Figure 40 Gases 02 - Compressed Air Zoned

Figure 41 Gases 03 - Methane Pipeline

Pipe Flow Expert Software

The Pipe Flow Expert software has been designed to help today’s engineers analyze and solve a wide range of problems where the flow and pressure losses throughout a pipe network must be determined.

Trial Mode Operation

You do not need a license code to run the trial version of the Pipe Flow Expert software. When the License Screen is shown, the software may be run by clicking the 'Run Free Trial' button.

The software is initially supplied in trial mode and this allows users to draw their own ‘small’ systems and gives access to the Example Systems, where the user can view the pipe model and ‘solve’ the system to see the calculated results.

The trial mode is intended to give users a means of assessing if the software is suitable for their application. Certain features of the software are fixed for the trial version. The trial mode operation is not intended to give full access to the software.

In trial mode, Pipe Flow Expert allows the user to:

a. Load Example Systems – no changes to the model are permitted.

Solve Example Systems to find the balanced steady state solution.

View Calculated Results on the drawing, in spreadsheet format, and in PDF reports.

b. Draw New Systems up to a maximum of 5 pipes – fluid is always set to water.

Solve the System.

View Calculated Results - in trial mode, systems cannot be saved.

Example Systems

The example systems supplied with Pipe Flow Expert may be loaded and solved using a trial installation of the software.

The example systems are divided into four categories:

a. Common Systems – Modelling Specific Items: Pipes, Fittings, Components, Valves and Pumps.

b. General Systems – Gravity Flow, Pumped Flow (3 pump types), Energy Recovery.

c. Isometric Systems – Chilled Water Cooling, Water Distribution Network, Fire Protection.

d. Gas Systems – Zoned Compressed Air Distribution, Methane Pipeline Isothermal Flow.

The examples range from simple systems with only a few pipes to more complex applications which contain over a hundred pipes. We suggest that each example system is opened and solved in turn, so that you become familiar with the features and modeling capabilities of the Pipe Flow Expert software.

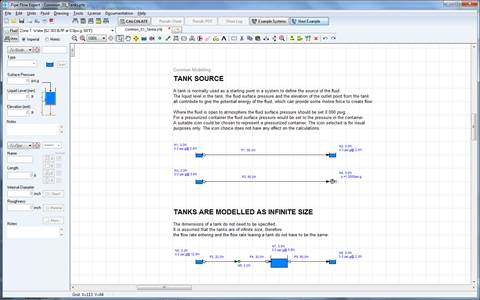

Common 01 - Tanks

Figure 1 Common 01 - Tanks

A tank is normally used as a starting point in a system to define the source of the fluid.

The liquid level in the tank, the fluid surface pressure and the elevation of the outlet point from the tank all contribute to give the potential energy of the fluid, which can provide some motive force to create flow.

Where the fluid is open to atmosphere the fluid surface pressure should be set 0.000 psig.

For a pressurized container the fluid surface pressure would be set to the pressure in the container.

A suitable icon can be chosen to represent a pressurized container. The icon selected is for visual purposes only. The choice of icon does not have any effect on the calculations.

The dimensions of a tank do not need to be specified. It is assumed that the tanks are of infinite size, therefore the flow rate entering and the flow rate leaving a tank do not have to be the same.

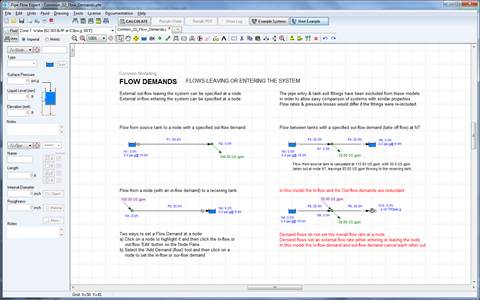

Common 02 - Flow Demands

Figure 2 Common 02 - Flow Demands

A flow demand specifies a flow leaving or entering a system from an external source.

External out-flow leaving the system can be specified at a node.

External in-flow entering the system can be specified at a node

The example shows four models that demonstrate the use of flow demands.

a. Flow from source tank to a node with a specified out-flow demand.

b. Flow from a node (with an in-flow demand) to a receiving tank.

c. Flow between tanks with a specified out-flow demand (take off flow) at an intermediate node.

d. A model with in-flow and the out-flow demands at the same node.

Note:

In the last model the flow demands have been set to the same value, which means the in-flow and the out-flow demands are redundant.

Demand flows do not set the overall flow rate at a node.

Demand flows set an external flow rate either entering or leaving the node point.

In this model the in-flow demand and out-flow demand cancel each other out.

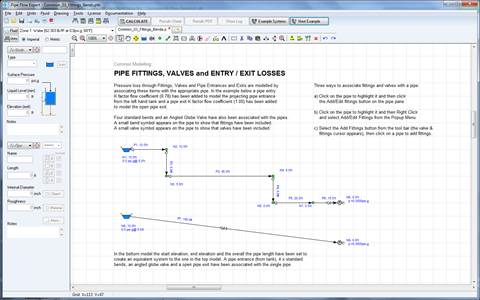

Common 03 - Pipe Fittings & Valves

Figure 3 Common 03 - Pipe Fittings & Valves

Pressure loss through Fittings, Valves and Pipe Entrances and Exits are modelled by associating these items with the appropriate pipe.

In these examples a pipe entry K factor flow coefficient (0.78) has been added to model the projecting pipe entrance from the left hand tank and a pipe exit K factor flow coefficient (1.00) has been added to model the open pipe exit.

Four standard bends and an Angled Globe Valve have also been associated with the pipes.

A small bend symbol appears on the pipe to show that fittings have been included.

A small valve symbol appears on the pipe to show that valves have been included.

The top example shows a pipe modelled as six separate sections. Each pipe section has a fitting or valve or entrance loss or exit loss associated with the individual section as appropriate.

A pipe with a constant diameter (which may consist of many short lengths - horizontal, risers, droppers, slopes etc) and fitting/valves may be modeled as one pipe in a Pipe Flow Expert schematic as shown in the bottom model.

In the bottom model the start elevation, end elevation and the overall the pipe length have been set to create an equivalent system to the one in the top model. A pipe entrance (from tank), 4 x standard bends, an angled globe valve and a open pipe exit have been associated with the single pipe.

When the system has been solved it can be seen that the flow rate in both models is the same.

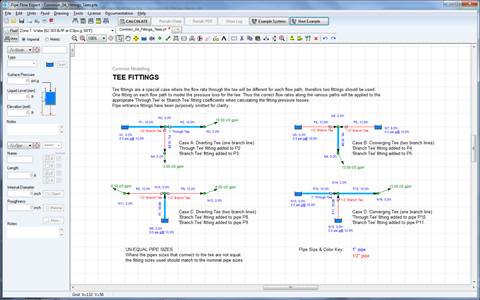

Common 04 - Tee Fittings

Figure 4 Common 04 - Tee Fittings

Tee fittings are a special case where the flow rate through the tee will be different for each flow path, therefore two fittings should be used.

One fitting is added on each flow path to model the pressure loss for the tee. The correct flow rates along the various paths will then be applied to the appropriate 'Through Tee' or 'Branch Tee' fitting coefficients when calculating the fitting pressure losses.

Pipe entrance fittings have been purposely omitted for clarity.

There are four different situations where a Tee fitting may occur in a system, which are modelled as follows:

Case A: Diverting Tee (one branch line)

'Through Tee' fitting added to the main pipe leaving the tee.

'Branch Tee' fitting added to branch line pipe leaving the tee.

Case B: Converging Tee (two branch lines)

'Branch Tee' fitting added to a pipe entering the tee.

'Branch Tee' fitting added to a pipe entering the tee.

Case C: Diverting Tee (two branch lines)

'Branch Tee' fitting added to a pipe leaving the tee.

'Branch Tee' fitting added to a pipe leaving the tee.

Case D: Converging Tee (one branch line)

'Through Tee' fitting added to the main pipe entering the tee.

'Branch Tee' fitting added to the branch line entering the tee

UN-EQUAL PIPE SIZES:

Where the pipes sizes that connect to the tee are not equal, the fitting sizes used should match to the nominal pipe sizes.

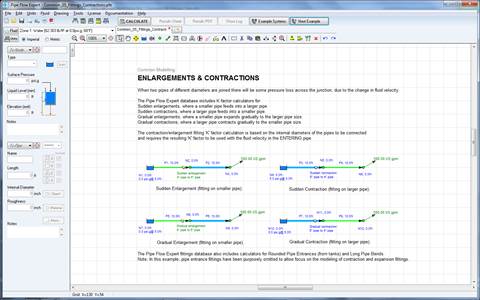

Common 05 - Enlargements & Contractions

Figure 5 Common 05 - Enlargements & Contractions

When two pipes of different diameters are joined there will be some pressure loss across the junction, due to the change in fluid velocity.

The Pipe Flow Expert database includes K factor calculators for:

a. Sudden enlargements, where a smaller pipe feeds into a larger pipe.

b. Sudden contractions, where a larger pipe feeds into a smaller pipe.

c. Gradual enlargements, where a smaller pipe expands gradually to the larger pipe size.

d. Gradual contractions, where a larger pipe contracts gradually to the smaller pipe size.

The contraction/enlargement fitting 'K' factor calculation is based on the internal diameters of the pipes to be connected and requires the resulting 'K' factor to be used with the fluid velocity in the ENTERING pipe.

Examples are shown for:

a. Sudden Enlargement (fitting on smaller pipe).

b. Sudden Contraction (fitting on larger pipe).

c. Gradual Enlargement (fitting on smaller pipe).

d. Gradual Contraction (fitting on larger pipe).

The Pipe Flow Expert fittings database also includes calculators for Rounded Pipe Entrances (from tanks) and Long Pipe Bends.

Note: In this example, pipe entrance fittings have been purposely omitted to allow focus on the modelling of contraction and expansion fittings.

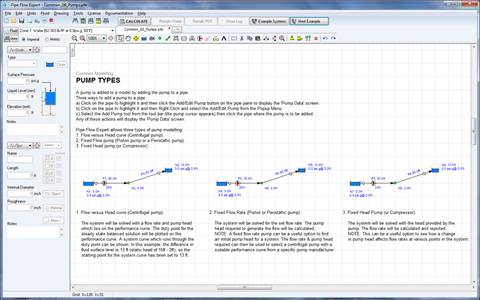

Common 06 - Pump Types

Figure 6 Common 06 - Pump Types

A pump is added to a model by adding the pump to a pipe.

Pipe Flow Expert allows three types of pump modelling:

1. Flow versus Head curve (Centrifugal pump):

The system will be solved with a flow rate and pump head which lies on the performance curve.

The duty point for the steady state balanced solution will be plotted on the performance curve.

A system curve which runs through the duty point can be shown. In the example shown, the difference in fluid surface level is 13 ft (static head of 15ft - 2ft), so the starting point for the system curve has been set to 13 ft.

2. Fixed Flow Rate (Piston or Peristaltic pump):

The system will be solved for the set flow rate. The pump head required to generate the flow will be calculated.

Note: A fixed flow rate pump can be a useful option to find an initial pump head for a system. The flow rate & pump head required can then be used to select a centrifugal pump with a suitable performance curve from a specific pump manufacturer.

3. Fixed Head Pump (or Compressor):

The system will be solved with the head provided by the pump. The flow rate will be calculated and reported.

Note: This can be a useful option to see how a change in pump head affects flow rates at various points in the system.

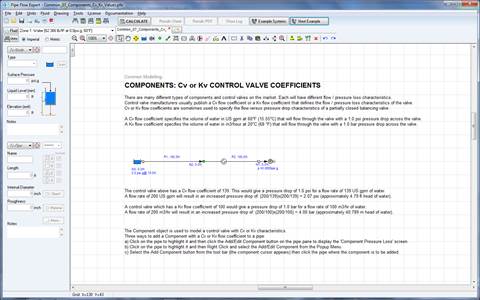

Common 07 - Cv or Kv Control Valve Coefficients

Figure 7 Common 07 - Cv or Kv Control Valve Coefficients

There are many different types of components and control valves on the market. Each will have different flow / pressure loss characteristics.

Control valve manufacturers usually publish a Cv flow coefficient or a Kv flow coefficient that defines the flow / pressure loss characteristics of the valve.

Cv or Kv flow coefficients are sometimes used to specify the flow versus pressure drop characteristics of a partially closed balancing valve.

A Cv flow coefficient specifies the volume of water in US gpm at 60°F (15.55°C) that will flow through the valve with a 1.0 psi pressure drop across the valve.

A Kv flow coefficient specifies the volume of water in m³/hour at 20°C (68 °F) that will flow through the valve with a 1.0 bar pressure drop across the valve.

The control valve in this example has a Cv flow coefficient of 139. This would give a pressure drop of 1.0 psi for a flow rate of 139 US gpm of water. A flow rate of 200 US gpm will result in an increased pressure drop of: (200/139) x (200/139) = 2.07 psi (approximately 4.79 ft head of water).

A control valve which has a Kv flow coefficient of 100 would give a pressure drop of 1.0 bar for a flow rate of 100 m³/hr of water. A flow rate of 200 m³/hr will result in an increased pressure drop of: (200/100) x (200/100) = 4.00 bar (approximately 40.789 m head of water).

In Pipe Flow Expert, add a Component object to a pipe to model a control valve with a Cv or Kv flow coefficient.

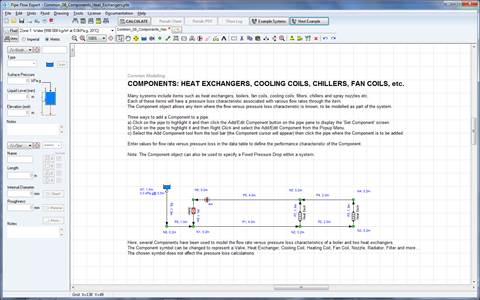

Common 08 - Heat Exchangers, Cooling Coils, Chillers, Fan Coils

Figure 8 Common 08 - Heat Exchangers, Cooling Coils, Chillers, Fan Coils

Many systems include items such as heat exchangers, boilers, fan coils, cooling coils, filters, chillers and spray nozzles etc.

Each of these items will have a pressure loss characteristic associated with various flow rates through the item.

The Component object allows any item where the flow versus pressure loss characteristic is known, to be modelled as part of the system.

Add a Component to a pipe and enter values for flow rate versus pressure loss in the data table to define the performance characteristic of the Component.

Note: The Component object can also be used to specify a Fixed Pressure Drop within a system.

In the example several Components have been used to model the flow rate versus pressure loss characteristics of a boiler and two heat exchangers.

The Component symbol can be changed to represent a Valve, Heat Exchanger, Cooling Coil, Heating Coil, Fan Coil, Nozzle, Radiator, Filter and more...

The chosen symbol does not affect the pressure loss calculations.

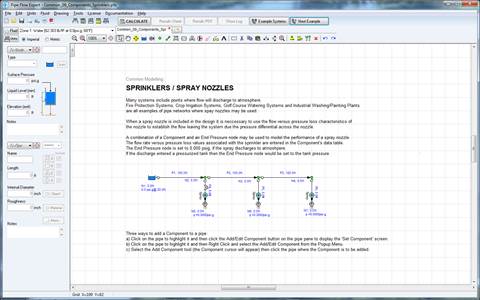

Common 09 - Sprinklers / Spray Nozzles

Figure 9 Common 09 - Sprinklers / Spray Nozzles

Many systems include points where flow will discharge to atmosphere.

Fire Protection Systems, Crop Irrigation Systems, Golf Course Watering Systems and Industrial Washing/Painting Plants are all examples of pipe networks where spay nozzles may be used.

When a spray nozzle is included in the design it is necessary to use the flow versus pressure loss characteristics of the nozzle to establish the flow leaving the system due the pressure differential across the nozzle.

A combination of a Component and an End Pressure node may be used to model the performance of a spray nozzle.

The flow rate versus pressure loss values associated with the sprinkler should be entered in the Component's data table.

The End Pressure node is set to 0.000 psig, if the spray discharges to atmosphere.

If the discharge entered a pressurized tank then the End Pressure node would be set to the tank pressure.

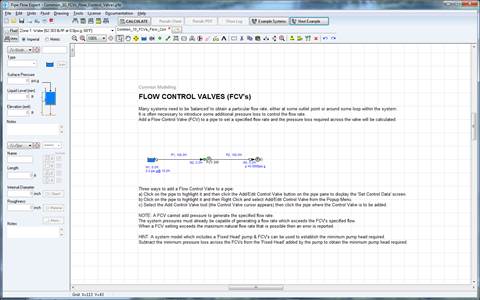

Common 10 - Flow Control Valves (FCVs)

Figure 10 Common 10 - Flow Control Valves

Many systems need to be 'balanced' to obtain a particular flow rate, either at some outlet point or around some loop within the system.

It is often necessary to introduce some additional pressure loss to control the flow rate.

Add a Flow Control Valve (FCV) to a pipe to set a specified flow rate and the pressure loss required across the valve in the solution of the final system will be calculated.

NOTE: A FCV cannot add pressure to generate the specified flow rate.

The system pressures must already be capable of generating a flow rate which exceeds the FCV's specified flow. When a FCV setting exceeds the maximum natural flow rate that is possible then an error is reported.

HINT: A system model which includes a 'Fixed Head' pump & FCVs can be used to establish the minimum pump head required. Subtract the minimum pressure loss across the FCVs from the 'Fixed Head' added by the pump to obtain the minimum pump head required.

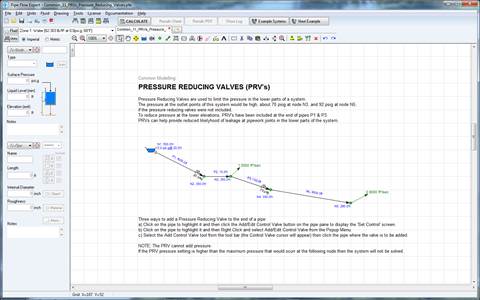

Common 11 - Pressure Reducing Valves (PRVs)

Figure 11 Common 11 - Pressure Reducing Valves

Pressure Reducing Valves are used to limit the pressure in the lower parts of a system.

The pressure at the outlet points of this system would be high, about 70 psig at node N3, and 92 psig at node N5, if the pressure reducing valves were not included.

To reduce pressure at the lower elevations, PRV's have been included at the end of pipes P1 & P3.

PRVs can help provide reduced likelihood of leakage at pipework joints in the lower parts of the system.

A Pressure Reducing Valve will always be positioned to the end of a pipe in a Pipe Flow Expert model.

NOTE: The PRV cannot add pressure.

If the PRV pressure setting is higher than the maximum pressure that would occur at the following node then the system will not be solved.

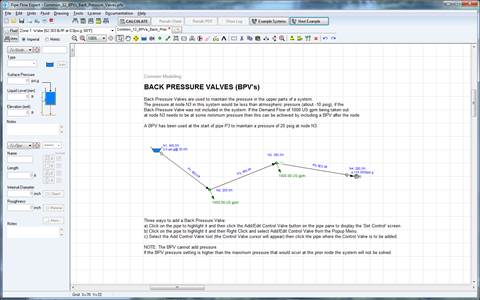

Common 12 - Back Pressure Valves (BPVs)

Figure 12 Common 12 - Back Pressure Valves

Back Pressure Valves are used to maintain the pressure in the upper parts of a system.

In this example the pressure at node N3 in this system would be less than atmospheric pressure (about -10 psig), if the Back Pressure Valve was not included in the system.

If the Demand Flow of 1000 US gpm being taken out at node N3 needs to be at some minimum pressure then this can be achieved by including a BPV after the node.

A BPV has been used at the start of pipe P3 to maintain a pressure of 20 psig at node N3.

A Back Pressure Valve will always be positioned to the start of a pipe in a Pipe Flow Expert model.

NOTE: The BPV cannot add pressure. If the BPV pressure setting is higher than the maximum pressure that would occur at the prior node, the system will not be solved.

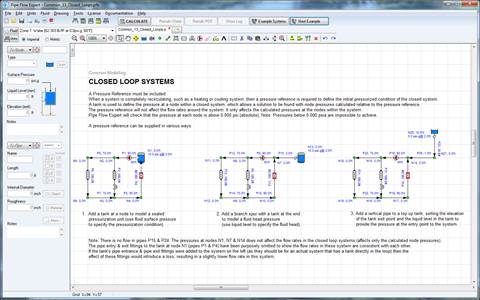

Common 13 - Closed Loop Systems

Figure 13 Common 13 - Closed Loop systems

A Pressure Reference must be included within a Closed Loop system:

When a system is completely recirculating, such as a heating or cooling system, then a pressure reference is required to define the initial pressurized condition of the closed system.

A tank is used to define the pressure at a node within a closed system, which allows a solution to be found with node pressures calculated relative to the pressure reference.

The pressure reference will not affect the flow rates around the system. It only affects the calculated pressures at the nodes within the system.

Pipe Flow Expert will check that the pressure at each node is above 0.000 psi (absolute).

Note: Pressures below 0.000 psia are impossible to achieve.

A pressure reference can be supplied in various ways:

1. Add a tank at a node to model a sealed pressurization unit (use fluid surface pressure to specify the pressurization condition).

2. Add a branch spur with a tank at the end to model a fluid head pressure (use liquid level to specify the fluid head).

3. Add a vertical pipe to a top up tank, setting the elevation of the tank exit point and the liquid level in the tank to provide the pressure at the entry point to the system.

Note: There is no flow in pipes that connect the pressure reference tanks to the closed loop systems. The pressures at the nodes where the tanks connect to the systems do not affect the flow rates in the closed loop systems (affects only the calculated node pressures).

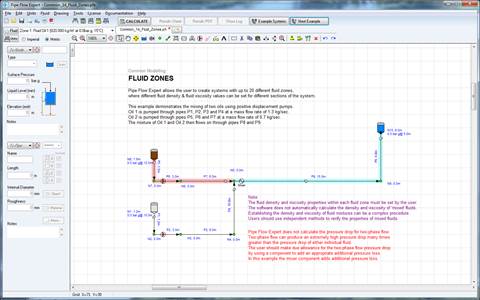

Common 14 - Fluid Zones

Figure 14 Common 14 - Fluid Zones

Pipe Flow Expert allows the user to create systems with up to 20 different fluid zones, where different fluid density & fluid viscosity values can be set for different sections of the system.

This example demonstrates the mixing of two oils using positive displacement pumps.

Oil 1 is pumped through pipes P1, P2, P3 and P4 at a mass flow rate of 1.3 kg/sec.

Oil 2 is pumped through pipes P5, P6 and P7 at a mass flow rate of 0.7 kg/sec.

The mixture of Oil 1 and Oil 2 then flows on through pipes P8 and P9.

Note:

The fluid density and viscosity properties within each fluid zone must be set by the user.

The software does not automatically calculate the density and viscosity of 'mixed' fluids.

Establishing the density and viscosity of fluid mixtures can be a complex procedure.

Users should use independent methods to verify the properties of mixed fluids.

In this example, the oil fluids mix together and the resulting fluid remains as a liquid, without a phase change. Some pressure loss occurs as a result of this process and the mixer component adds additional pressure loss.

Two Phase Flow:

Pipe Flow Expert does not calculate the pressure drop for two-phase flow.

If a fluid changes state (from liquid to gas, or from gas to liquid), i.e. it transitions from one phase to another, then this two-phase flow can produce an extremely high pressure drop that is many times greater than the pressure drop which would occur if the fluid remained in the same state. The user should make due allowance for two-phase flow pressure drop by using a component to add an appropriate additional pressure loss.

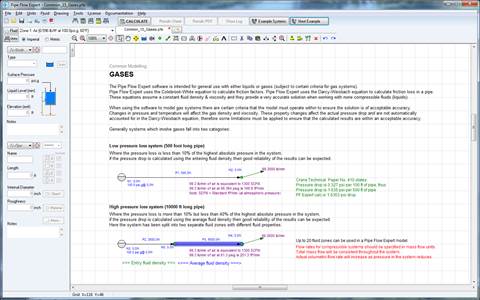

Common 15 - Gases

The Pipe Flow Expert software is intended for general use with either liquids or gases (subject to certain criteria for gas systems). Pipe Flow Expert uses the Colebrook-White equation to calculate friction factors. Pipe Flow Expert uses the Darcy-Weisbach equation to calculate friction loss in a pipe. These equations assume a constant fluid density & viscosity and they provide a very accurate solution when working with none compressible fluids (liquids).

When using the software to model gas systems there are certain criteria that the model must operate within to ensure the solution is of acceptable accuracy. Changes in pressure and temperature will affect the gas density and viscosity. These property changes affect the actual pressure drop and are not automatically accounted for in the Darcy-Weisbach equation, therefore some limitations must be applied to ensure that the calculated results are within an acceptable accuracy.

Generally systems which involve gases fall into two categories:

Low pressure loss system:

Where the pressure loss is less than 10% of the highest absolute pressure in the system, if the pressure drop is calculated using the entering fluid density then good reliability of the results can be expected.

High pressure loss system:

Where the pressure loss is more than 10% but less than 40% of the highest absolute pressure in the system, if the pressure drop is calculated using the average fluid density then good reliability of the results can be expected.

This high pressure loss system has been split into two separate fluid zones with different fluid properties. Up to 20 fluid zones can be used in a Pipe Flow Expert model.

Flow rates for compressible systems should be specified in mass flow units. Total mass flow will be consistent throughout the system. Actual volumetric flow rate will increase as pressure in the system reduces.

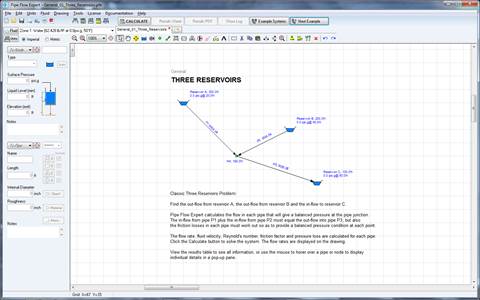

General 01 - Three Reservoirs

Figure 16 General 01 - Three Reservoirs

Classic Three Reservoirs Problem found in most text books on fluid mechanics and hydraulics:

Three reservoirs are each located at different elevations and are joined at a common point by three pipes. Water will flow from the highest reservoir towards the join point. It is also likely that water will flow from the second highest reservoir towards the join point (this would not always be the case if the elevations and pipe sizes were changed).

The flow into the join point must be equal to the flow out of the join point (Balanced flow).

Find the outflow from reservoir A, the outflow from reservoir B and the in-flow to reservoir C.

Pipe Flow Expert calculates the flow in each pipe that will give a balanced pressure at the pipe junction.

The in-flow from pipe P1 plus the in-flow from pipe P2 must equal the out-flow into pipe P3 giving a balanced flow condition, also the friction losses in each pipe must work out so as to provide a balanced pressure condition at each point.

The flow rate, fluid velocity, Reynolds number, friction factor and pressure loss are calculated for each pipe.

Click the Calculate button to solve the system. The flow rates are displayed on the drawing.

View the results table to see all information, or use the mouse to hover over a pipe or node to display

individual pipe details in a pop-up pane.

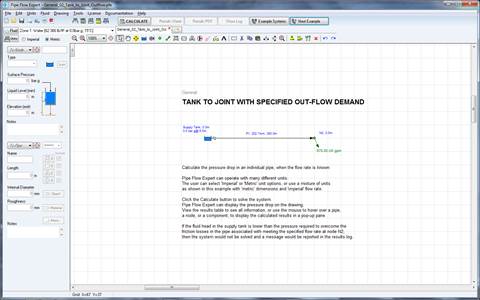

General 02 - Tank to Joint Outflow

Figure 17 General 02 - Tank to Joint Outflow

Calculate the pressure drop in an individual pipe, when the flow rate is known:

Pipe Flow Expert can operate with many different units. The user can select 'Imperial' or 'Metric' unit options, or use a mixture of units as shown in this example with 'metric' dimensions and 'imperial' flow rate.

Click the Calculate button to solve the system. Pipe Flow Expert can display the pressure drop on the drawing. View the results table to see all information, or use the mouse to hover over a pipe, a node, or a component, to display the calculated results in a pop-up pane.

If the fluid head in the supply tank is lower than the pressure required to overcome the friction losses in the pipe with the specified discharge flow rate at node N2, then the system would not be solved and a message would be reported in the results log.

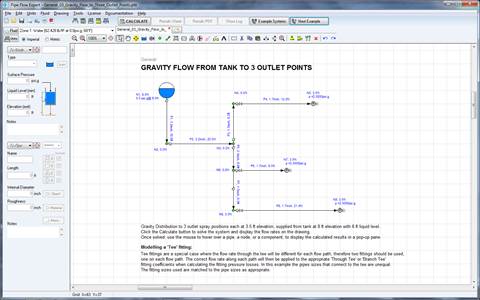

General 03 - Gravity Flow to 3 Outlet Points

Figure 18 General 03 - Gravity Flow to 3 Outlet Points

Gravity Distribution to 3 outlet spray positions each at 3.5 ft elevation, supplied from a tank at 8 ft elevation with 6 ft liquid level.

Click the Calculate button to solve the system and display the flow rates on the drawing. Once solved, use the mouse to hover over a pipe, a node, or a component, to display the calculated results in a pop-up pane.

Modelling a 'Tee' fitting:

Tee fittings are a special case where the flow rate through the tee will be different for each flow path, therefore two fittings should be used, one fitting on each flow path. The correct flow rate along each path will then be applied to the appropriate 'Through Tee' or 'Branch Tee' fitting coefficients when calculating the fitting pressure losses.

In this example the pipes sizes that connect to the tee are unequal. The fitting sizes used are matched to the pipe sizes as appropriate.

General 04 - Fixed Flow Pumping to 3 Tanks

Figure 19 General 04 - Fixed Flow Pumping to 3 Tanks

Pump set to a specified fixed flow rate:

This system models a fixed flow rate pump transferring 250 l/min of fluid from a supply container to 3 holding tanks. The flow rates to the top tank & the center tank are controlled by two FCVs each set at 80 l/min (pipe P6, pipe P12). The balance of the flow, 90 l/min, is forced along the path to the bottom tank (pipe P15).

Click the Calculate button to solve the system, to find the pump head required.

Pipe Flow Expert can be configured to display the flow rates, fluid velocity or total pressure drop on the drawing. View the results sheet or use the mouse to hover over a pipe, a node, or a component, to display the calculated results in a pop-up pane.

NOTE: When a fixed flow rate pump is used to control the total flow and FCVs are used to control flow in certain downstream pipes, there must always be at least one path through the system where the flow rate is not controlled by a FCV (since it will effectively be controlled anyway by the specified total flow rate minus the sum of the controlled flows in the other paths).

If a Flow Control Valve set at 80 l/min was fitted to pipe P15 then the total outlet flow would not equal the total pump flow rate and hence it would not be possible to find a balanced solution for the system.

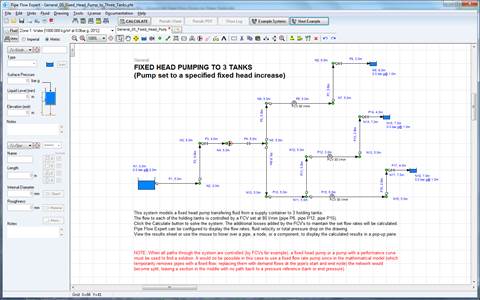

General 05 - Fixed Head Pumping to 3 Tanks

Figure 20 General 05 - Fixed Head Pumping to 3 Tanks

This example demonstrates a common situation encountered in fluid transfer situations where the required pump head has to be determined.

The system models a fixed head pump transferring fluid from a supply container to 3 holding tanks.

The flow to each of the holding tanks is controlled by a FCV set at 80 l/min (pipe P6, pipe P12, pipe P15).

The problem is to determine the pump head needed to deliver the total flow. A fixed head pump is used to add pressure to the model. An initial added pressure of 20m head of water has been chosen as a possible solution.

If the added pump head had been set too low it would not be possible to solve the system.

When the system is solved, the additional pressure loss introduced by the Flow Control Valves to regulate the flow to each tank is calculated.

The FCV on P12, set to a flow of 80 l/min has introduced the least head loss of any flow control at 2.266 m head. Therefore a pump is required that can deliver a flow of 240 l/min and add a minimum of 17.734 m head (20.0 – 2.266).

Pipe Flow Expert can be configured to display the flow rates, fluid velocity or total pressure drop on the drawing. View the results sheet or use the mouse to hover over a pipe, a node, or a component, to display the calculated results in a pop-up pane.

NOTE: When all paths through the system are controlled (by FCVs for example), a fixed head pump or a pump with a performance curve must be used to find a solution. In this case, it would not be possible to use a fixed flow rate pump since in the mathematical model (which temporarily removes pipes with a fixed flow, replacing them with demand flows at the pipe's start and end node) the network would become split, leaving a section in the middle with no path back to a pressure reference (tank or end pressure).

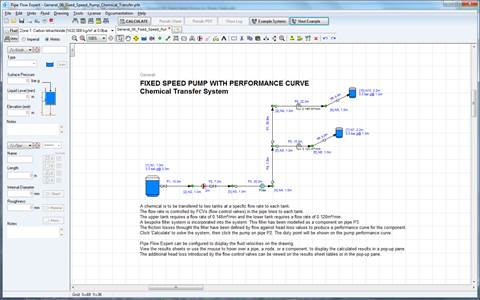

General 06 - Fixed Speed Pump with Performance Curve

Figure 21 General 06 - Fixed Speed Pump with Performance Curve

This system design includes a stainless steel pump that is used to transfer a chemical to two tanks at a set flow rate to each tank. The pump runs at a fixed speed producing a flow rate and pressure which will intersect with the system curve.

The flow to each tank is regulated by a FCV (flow control valve) that is set to limit the flow rate. The system includes a special filter which has been modeled by adding a Component to pipe P3.

Component pressure losses can be a Fixed Loss (independent of flow rate), or can be modeled as a Component Curve Loss when the pressure loss will vary as the flow rate is changed.

All the flow rates in the system are determined by the flow control valves. To find a ‘Balanced Pressure Condition’ for the solution, the fluid head provided by the pump (this will be constant for a specified flow rate) must be counter-acted by the additional resistance (pressure loss) provided by the flow control valves.

Note: If a Flow Control Valve flow rate setting is higher than the flow rate that would occur naturally in the pipe then the flow control valve will be unable to operate (a flow control valve cannot add fluid head to increase the flow rate). A warning would be issued in the Results Log: >>> System not solved. Flow control settings not met. In this case, either remove the flow control valve or reduce the specified flow rate of the control.

Generally it is not recommended that flow rate in all paths are controlled, although this is often done for expediency. A design based on limiting the flow in all paths may not be an efficient design. The pump must be ‘over-sized’ in order for the system to work.

Note: If the pump head available is not high enough to meet the FCVs set flow rates then Pipe Flow Expert will be unable to calculate a solution.

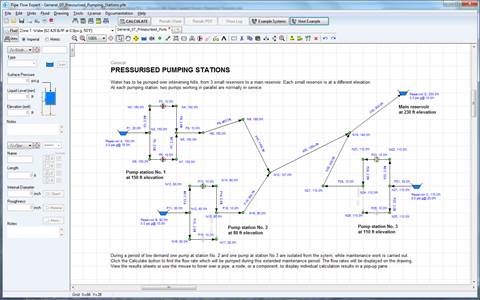

General 07 - Pressurized Pumping Stations

Figure 22 General 07 - Pressurized Pumping Stations

This example demonstrates the power and flexibility of the Pipe Flow Expert software. Some pipes and pumps have been temporarily removed from the system, leaving isolated legs where flow will not occur. Pipe Flow Expert is able to identify this situation and find a solution for the remainder of the pipe network.

Water is to be transferred from 3 small reservoirs to a main reservoir. All the reservoirs are located at different elevations. The motive force is normally provided by 6 pumps, but two of the pumps have been taken out of service while major maintenance is carried out.

A Balanced Flow and a Balanced Pressure solution has to be found that coincides with a point on the performance curve of each pump that is in operation.

The pump performance is specified by entering the flow rate, fluid head, efficiency and NPSHr for a number of operating points. The Pump Data screen allows the data to be entered and the Pump Performance Curve to be drawn.

Where a pump has been taken out of service, a pipe has been closed to prevent recirculation of the flow, and the pump has been disabled by un-checking the ‘Include pump’ check box on the Pipe Pane.

In results mode the operating point of a pump can be plotted on the pump performance graph. Limits may be set to define the Preferred Operating Range of a pump. If the operating point of the pump falls outside the preferred operating range, a warning will be shown in the results table. Water has to be pumped over intervening hills, from 3 small reservoirs to a main reservoir. Each small reservoir is at a different elevation.

Click the Calculate button to find the flow rate which will be pumped during this extended maintenance period. The flow rates will be displayed on the drawing.

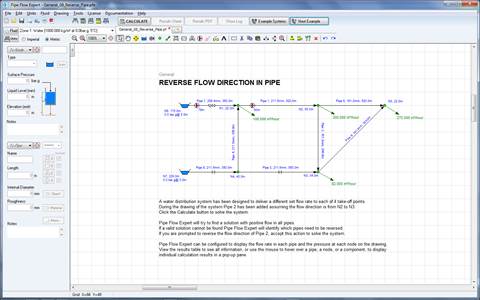

General 08 - Reverse Pipe

Figure 23 General 08 - Reverse Pipe

A water distribution system has been designed to deliver a different set flow rate to each of 4 take-off points. During the drawing of the system, Pipe 2 has been added assuming the flow direction is from N2 to N3.

Pipe Flow Expert will try to find a solution with positive flow in all pipes. If a valid solution cannot be found, Pipe Flow Expert will identify which pipes need to be reversed.

If you are prompted to reverse the flow direction of Pipe 2, accept this action to solve the system.

The results log will include an entry like the one below to identify which pipe(s) have been reversed.

NEGATIVE FLOW: Solution found with flow showing as negative in some pipes.

The following pipe directions have been reversed to give a solution with positive flows:

Pipe 2 flow direction changed to show positive flow.

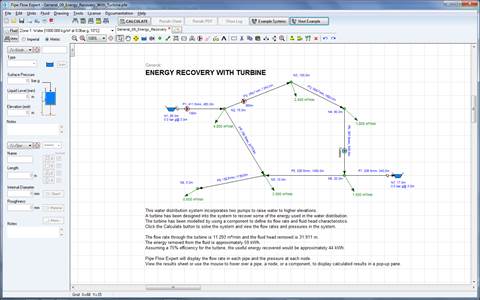

General 09 - Energy Recovery with Turbine

Figure 24 General 09 - Energy Recovery with Turbine

This water distribution system incorporates two pumps to raise water to higher elevations. A turbine has been designed into the system to recover some of the energy used in the water distribution.

The turbine has been modeled by using a component and a component curve loss to define the flow rate and fluid head removal characteristics of the turbine.

The operation of a turbine is similar to a pump in reverse. Fluid head is removed from the system by the turbine (a pump adds fluid head to the system).

Note: A pump cannot be modeled with negative entries for flow or fluid head. This design has been adopted to try and reduce errors when pump performance data is being entered. Therefore it is not possible to use a pump component to model a turbine.

Even though the water distribution system has 3 take-off points, before the water flow enters the turbine it is still possible to recover a significant amount of energy from the turbine.

The flow rate through the turbine is 11.293 m³/min and the fluid head removed is 31.911 m.

The energy removed from the fluid is approximately 59 kWh.

Assuming a 75% efficiency for the turbine, the energy recovered would be approximately 44 kWh.

Useful Formulae: Power for pumping assuming 100% pump efficiency

KW = mass flow (kg/s) x energy gain (m hd) x g ÷ 1000

Where g = acceleration due to gravity = 9.80665 m/s².

HP = mass flow (lbs/min) x energy gain (ft hd) ÷ 33000 ft lbs/min

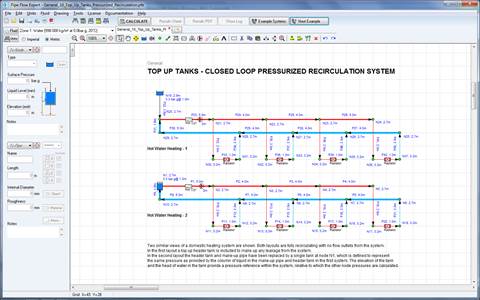

General 10 - Top Up Tanks - Closed Loop Pressurized Recirculation System

Figure 25 General 10 - Top Up Tanks - Close Loop Pressurized System

Two similar views of a domestic heating system are shown. Both layouts are fully recirculating with no flow outlets from the system.

In the first layout a top up header tank is included to make up any leakage from the system.

In the second layout, the header tank and make-up pipe have been replaced by a single tank at node N1, which is defined to represent the same pressure as provided by the column of liquid in the make-up pipe and header tank in the first system.

The elevation of the tank and the head of water in the tank provide a pressure reference within the system, relative to which the other node pressures are calculated. When a system is completely recirculating, such as a heating or cooling system, or a sealed heat recovery system, the user must provide a starting pressure reference to allow a solution to be calculated that gives the pressure at each node.

Note: Pipe Flow Expert will check that the pressure at each node is above 0.000 psi (absolute). Pressures below 0.000 psia are impossible to achieve.

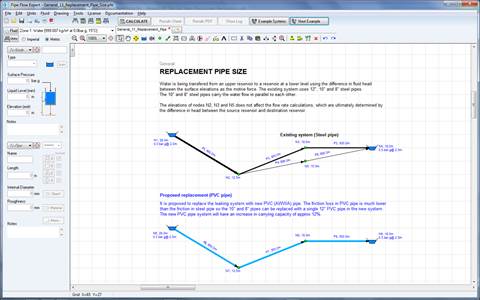

General 11 - Replacement Pipe Size

Figure 26 General 11 - Replacement Pipe Size

Water is being transferred from an upper reservoir to a reservoir at a lower level using the difference in fluid head between the surface elevations as the motive force. The existing system uses 12", 10" and 8" steel pipes. The 10" and 8" steel pipes carry the water flow in parallel to each other.

The elevation of the nodes, N2, N3 and N5 do not affect the flow rate calculations, which are ultimately determined by the difference in head between the source reservoir and destination reservoir.

Proposed replacement (PVC pipe):

It is proposed to replace the leaking system with new PVC (AWWA) pipe. The friction loss in PVC pipe is much lower than the friction in steel pipe so the 10" and 8" pipes can be replaced with a single 12" PVC pipe in the new system.

The new PVC pipe system will have an increase in carrying capacity of approx 12%.

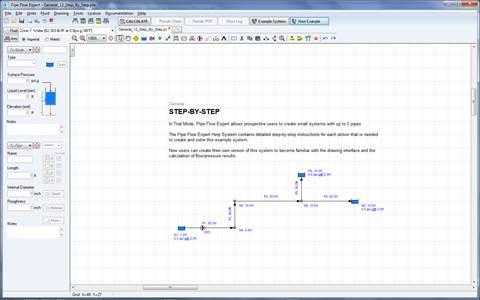

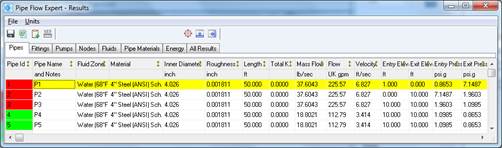

General 12 - Step By Step (User Created Example)

Figure 27 General 12 - Step By Step

This section provides a step-by-step walkthrough example that shows how to create and solve a system that contains 5 pipes, 3 tanks and one pump. It explains how to design the system, calculate the solution and view the results.

Note: When Pipe Flow Expert is operating in trial mode, a maximum of 5 pipes can be drawn and the system cannot be saved. A licensed version of Pipe Flow Expert allows up to 1000 pipes in a single system.

Create a System using the following Step-by-Step Instructions:

1. Select new grid – Click new grid tool button.

2. Click yes at prompt to create a new grid. - Click no to reject the isometric grid option

.

3. Click the Imperial radio button to change the units to the imperial defaults.

4. Click yes to accept the Imperial default units

Adding the tanks:

5. Click the ‘Tank button’ on the tool bar, , the drawing cursor will change to a pointer and a tank symbol.

, the drawing cursor will change to a pointer and a tank symbol.

6. Click on the grid, in the left hand quarter of the grid and about half way down the screen.

7. A tank will be drawn on the grid and the node pane will show the tank details.

8. Leave the tank surface pressure as 0.000 psig (the tank is open to atmosphere).

9. Edit the liquid level value, enter 2.000 (the liquid level in the tank is set to 2.000 ft).

10. Edit the bottom elevation value, enter 1.000 (the tank is located at 1.000 ft above your datum).

11. Move the cursor to a position about 12 grid intervals to the right and 2 grid intervals above the original tank position and click on the grid.

12. A second tank will be drawn on the grid and the node pane will show the tank details.

13. Leave the tank surface pressure as 0.000 psig (the tank is open to atmosphere).

14. Edit the liquid level value, enter 2.000 (the liquid level in the tank is set to 2.000 ft).

15. Edit the bottom elevation value, enter 10.000 (the tank is located at 10.000 ft above your datum).

16. Move the cursor to a position about 4 grid intervals to the left and 2 grid intervals above the second tank position and click on the grid.

17. A third tank will be drawn on the grid and the node pane will show the tank details.

18. Leave the tank surface pressure as 0.000 psig (the tank is open to atmosphere).

19. Edit the liquid level value, enter 2.000 (the liquid level in the tank is set to 2.000 ft).

20. Edit the bottom elevation value, enter 10.000 (the tank is located at 10.000 ft above your datum).

Adding the first pipe:

21. Click the ‘Add pipes button’ on the toolbar, , the drawing cursor will change to a pointer with a node/pipe link symbol.

, the drawing cursor will change to a pointer with a node/pipe link symbol.

22. Click the tank on the left of the drawing, to indicate that a pipe will be drawn from this node.

23. Move the cursor and the ‘Rubber banding’ line will appear to show where a pipe will be drawn.

24. Click at a grid intersection about 4 squares to the right of the tank.

25. A first pipe reminder message will appear, click yes to change the defaults.

Select the default pipe size

26. The Configuration Options – Pipe Defaults Tab is shown.

27. Click the Material button, , to display the list of pipe material types.

, to display the list of pipe material types.

28. Scroll to choose Steel (ANSI) Sch. 40, highlight this line, click the ‘Select’ button (or double click on the Steel (ANSI) Sch. 40 line).

29. A list of pipe sizes will be displayed.

30. Scroll to choose 4” Nominal Size, highlight this line, click the ‘Use selected size’ button (or double click on the 4” Nominal Size line).

31. The chosen size is now displayed in the top pane of the Pipe diameter data window.

32. Click the ‘Save Data to Pipe’ button to set the default pipe values.

33. Edit the length value, enter 50 (the length of the default pipe is set to 50 ft)

34. Click the OK button to confirm the changes.

35. The details of Pipe 1 have now changed to match the default pipe details.

Add further pipes

36. Move the rubber band to a position about 2 grid intervals above the previous node and click on the grid to draw a vertical line in an upward direction.

37. Pipe 2 has been added, the details of Pipe 2 match the default pipe details.

38. Move the rubber band to a position about 4 grid intervals to the right of the previous node and click to draw a horizontal line.

39. Pipe 3 has been added, the details of Pipe 3 match the default pipe details.

40. Move the rubber band to draw a further horizontal line, click the grid when the cursor is on the tank at the right hand side of the grid.

41. Pipe 4 has been added, the details of Pipe 4 match the default pipe details.

Add a pipe at a new position

42. Right click the mouse to switch off the rubber banding and the pipe drawing.

43. Click the pipe node directly below the tank at the top of the grid (this should be N6).

44. The node will be highlighted and the rubber banding will re-appear.

45. Move the rubber band to draw to draw a vertical line, click on the tank at the top of the grid.

46. Pipe 5 has been added, the details of Pipe 5 match the default pipe details.

47. Right click the mouse to switch off the rubber banding and the pipe drawing.

Note: If Pipe Flow Expert is operating in trial mode the maximum number of pipes allowed has been reached.

Setting the Node Elevations

As pipes are added, the elevations of the node at the end of each pipe, will have been set to match the elevation of the node at the start of the pipe.

The elevations of node N5 and node N6 need to be changed.

48. Click the ‘Show item button’ on the toolbar,  .

.

49. Select Node 5, click node 5 on the drawing to choose this node. A highlight circle will be shown around the node. The node details will be displayed in the node pane.

50. Edit the Elevation of join value, enter 10.000 (the elevation is set to 10.000 ft).

51. Select Node 6, click node 6 on the drawing to choose this node. A highlight circle will be shown around the node. The node details will be displayed in the node pane.

52. Edit the Elevation of the node, enter 10.000 (the elevation is set to 10.000 ft).

Moving the Tanks and Nodes

53. To re-position items on the grid click the ‘Drag and Move’ button on the tool bar, .

.

All nodes, tanks, and text labels will be highlighted with a yellow circle.

54. Click on a yellow circle and drag the item to a new position.

55. Right click the mouse to turn off the ‘Drag and Move’ feature.

Note: Text labels associated with a node or a pipe can only be moved within the area around a node. Pipe labels can only be moved within the area between the start and end of the pipe.

56. To move more than one Tank or Node and the attached pipes, click the  ‘Selection tool’ button on the tool bar.

‘Selection tool’ button on the tool bar.

57. Click on the grid, holding the mouse down to drag the selection rectangle to enclose the nodes to be moved, and then release the mouse. Click in the selection rectangle, holding the mouse down, and move the selected nodes to a new position.

58. Right click the mouse to turn off the ‘Selection’ feature

Add a pump

59. Click the ‘Show Item Info’ button on the tool bar,  .

.

60. Select Pipe 1: click pipe 1 on the drawing to choose this pipe. A highlight bar will be shown around the pipe.

61. Click the pump symbol, , in the pipe pane to open the pump dialog.

, in the pipe pane to open the pump dialog.

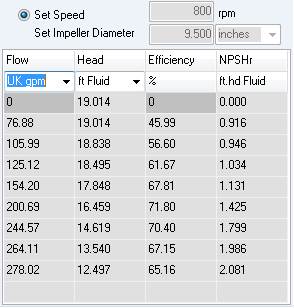

62. Enter this performance data for the pump: (or load pump data from database see step 64)

Note: Flow units are UK gpm

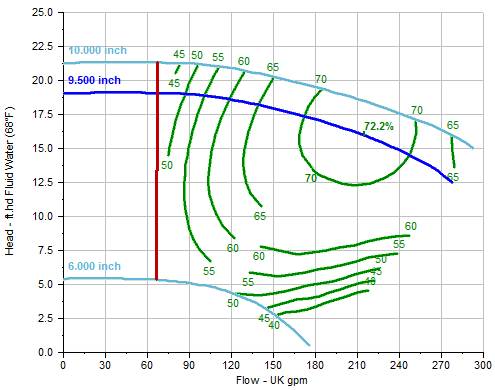

63. Click the ‘Draw Graph’ button to view the pump performance graph.

64. The pump data may also be loaded from the pump database.

a. Click the Open Pump Database tab on the pump screen.

b. Click the browse radio button & select the ‘GenericPumps_EndSuction_50Hz’ folder from the drop down list.

c. Browse the pump list and select the Generic_4x3-10H_A40_1475.pfpm’ entry.

d. The pump performance graph will be shown.

e. Click the ‘Select’ button to load the pump information on to the pump data screen.

f. Amend the pump speed to 800 rpm by using the up/down adjustment arrows.

g. Amend the pump impeller diameter to 9.50 inch by using the up/down adjustment arrows.

65. Set the pump distance ‘Along pipe’ to 20ft and the ‘at Elevation’ to 1.0 ft.

66. Click the ‘Save to Pipe’ button to close the Pump dialog.

67. The Pump symbol is now shown on Pipe 1.

Solving the system

68. Click the ‘Calculate’ button on the tool bar to find a balanced flow and a balanced pressure state for the system.

69. The Results Log should appear and confirm that the network was solved successfully

70. Three comments in the log warn the user that flow comes in from a tank and flow discharges from a pipe, but no fitting with a K factor to represent these effects have been included. Ignore these warning for this example.

71. Click the ‘View Results Sheet’ button to view the Results tables.

The results can also be viewed on the drawing.

72. Close the ‘Results Sheet’ to view the results on the drawing only, or Click the ‘View Results Drawing’ button if you did not click ‘View Results Sheet’ previously.

73. Hover over a pipe, node or tank on the drawing to display the results in the pop-up data panel. Click an item to display data in the status pane.

74. Click the pump symbol on Pipe 1 to view the pump operating point.

Re Design the system

75. To make amendments to the system design, click the Re-Design button.

76. Click the ‘Show Item Info’ button on the toolbar, .

.

77. Select the tank at the right hand side of the drawing (Node 2). Click on the drawing to choose this tank. A highlight circle will be shown around the tank. The tank details will be displayed in the node pane.

78. Edit the Bottom Elevation of tank, enter 9.000 (the elevation is set to 9.000 ft), the pipe P4 will now be assumed to fall 1.000 ft over its length (from 10 ft elevation to 9 ft elevation). This will allow more water to flow along this pipe.

79. Click the ‘Calculate’ button on the toolbar to find a balanced flow and a balanced pressure state for the new system design.

The user may wish to add a pipe entry fitting, pipe exit fittings & tee fittings to complete the model.

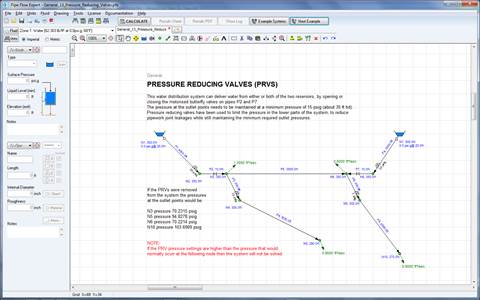

General 13 - Pressure Reducing Valves

Figure 28 General 13 - Pressure Reducing Valves

This water distribution system can deliver water from either or both of the two reservoirs, by opening or closing the motorised butterfly valves on pipes P2 and P7.

The pressure at the outlet points needs to be maintained at a minimum pressure of 15 psig (about 35 ft hd).

PRVs (pressure reducing valves) have been used to limit the pressure in the lower parts of the system, to reduce pipework joint leakages while still maintaining the minimum outlet pressures.

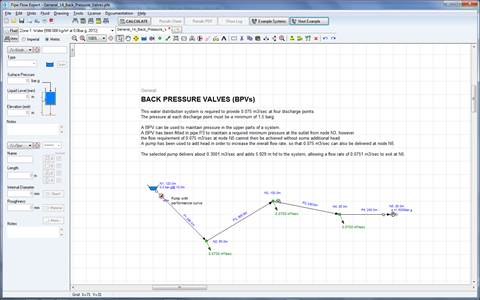

General 14 - Back Pressure Valves

Figure 29 General 14 - Back Pressure Valves

This water distribution system is required to provide a flow of 0.075 m³/sec at four discharge points.

The pressure at each discharge point must be a minimum of 1.5 bar g.

A BPV (back pressure valve) can be used to maintain pressure in the upper parts of a system.

A BPV has been fitted in pipe P3 to maintain a required minimum pressure at the outlet from node N3, however the flow requirement of 0.075 m³/sec at node N5 cannot then be achieved without some additional head (additional pressure). A pump has been used to add head in order to increase the overall flow rate, so that 0.075 m³/sec can also be delivered at node N5.

The selected pump delivers about 0.3001 m³/sec and adds 5.929 m hd to the system, allowing a flow rate of 0.0751 m³/sec to exit at N5.

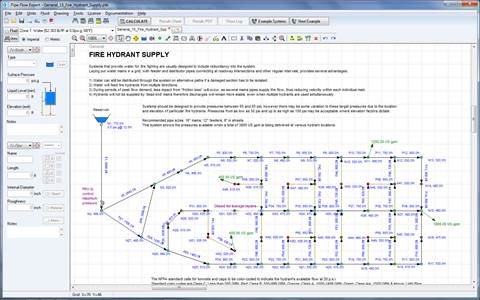

General 15 - Fire Hydrant Supply

Figure 30 General 15 - Fire Hydrant Supply

Systems that provide water for fire fighting are usually designed to include redundancy in the system. Laying out water mains in a grid, with feeder and distributor pipes connecting at roadway intersections and other regular intervals, provides several advantages:

1. Water can still be distributed throughout the system, even if a damaged section has to be isolated.

2. Water will feed fire hydrants from multiple directions.

3. During periods of peak flow demand, less impact from "friction loss" will occur, as several mains pipes supply the flow, thus reducing velocity within each individual main.

4. Hydrants will not be supplied by 'dead end' mains therefore discharges will remain more stable, even when multiple hydrants are used simultaneously.

Systems should be designed to provide pressures between 65 and 85 psi, however there may be some variation to these target pressures due to the location and elevation of particular fire hydrants. Pressures from as low as 50 psi, and up to as high as 100 psi, may be acceptable, when changes in elevation affect the available pressure at different points in the pipe network.

Recommended pipe sizes:

16" diameter main pipes

12" diameter feeder pipes

8" diameter street pipes

This system shows the pressures that are available when a total of 3800 US gpm is being delivered at various hydrant locations.

Isometric 01 - Chilled Water Cooling

Figure 31 Isometric 01 - Chilled Water Cooling

The system distributes chilled water to several buildings in a desert environment.

During periods of extreme temperature, stand-by equipment may be brought into operation.

The calculated solution shows the flows and pressures throughout the system under normal conditions when the following are all fully operational:

2 x Air Cooled Liquid Chillers

2 x Chilled Water Pumps

3 x Air Handling Units

1 x Fan Coil Unit

'Stand-By' equipment not in operation:

1 x Air Cooled Liquid Chiller

1 x Chilled Water Pump

3 x Air Handling Units

1 x Fan Coil Unit

Appropriate pipes have been closed to isolate the 'Stand-By' parts of the circuit.

Isometric 02 - Chilled Water Campus Cooling

Figure 32 Isometric 02 - Chilled Water Campus Cooling

This system uses ring main flow and return loops to connect 3 chiller plants and 18 campus areas which require cooling. The design incorporates a block of 4 major distribution pumps and provides flexibility to share the chiller loads throughout the system.

It has been necessary to introduce FCVs (flow control valves) at various points in the system, to restrict flows to certain areas, so that the required flow rate can be met in other parts of the system.

The initial design had an energy usage of 345 horsepower at peak demand. The elimination of some flow control valves, the amendment of some pipe diameters, selection of pumps to closely match the flow and head requirements and the introduction of a supplementary pump has allowed the energy usage to be reduced.

The revised design has allowed the energy usage to be reduced to 286.4 horsepower, providing a 17% energy saving.

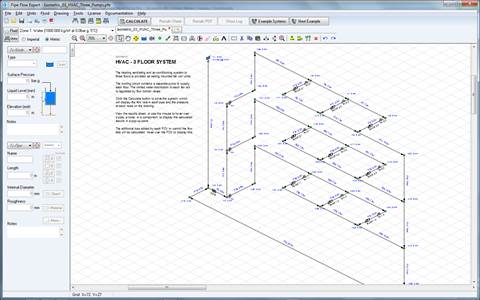

Isometric 03 - HVAC 3 Pumps

Figure 33 Isometric 03 - HVAC 3 Pumps

The heating ventilating and air-conditioning system to three floors is provided via ceiling mounted fan coil units. The cooling circuit contains a separate pump to supply each floor. The chilled water distribution to each fan coil is regulated by FCVs (flow control valves).

The fan coil units have been modeled as a Component Curve Loss where the pressure loss will vary as the flow rate is changed.

A water chiller unit is part of the common circuit of the system and this item has also been modelled as a Component with a flow versus pressure loss performance curve.

A header tank has been provided at N1, to provide a flooded suction inlet condition for the pump on the upper floor. The pump manufacturer recommends that the pumps should be used with a Flooded Suction inlet condition.

Click the Calculate button to solve the system. The results on the drawing now display the flow rate in each pipe and the pressure at each node. View the Results Sheet, or use the mouse to hover over a pipe, a node, or a component, to display the calculated results in a pop-up pane.

The pressure loss added by each FCV to control the flow rate will be calculated. Hover over the FCV to display this.

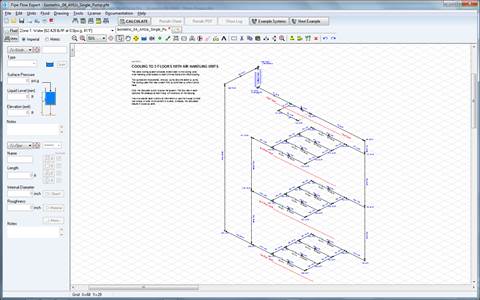

Isometric 04 - AHUs Single Pump

Figure 34 Isometric 04 - AHUs Single Pump

The cooling system provides chilled water to the cooling coils of air handling units, located on each of three floors of an office building.

Two pumps are incorporated, one duty pump and one stand by pump. The flow rate of cooling water to each AHU (air handling unit) is controlled by a flow control valve.

Click the Calculate button to solve the system. The flow rate in each pipe and the pressure at each node will be shown on the drawing. View the Results Sheet to show the information in tabular format or use the mouse to hover over a pipe, a node, a component or a valve, to display the calculated results in a pop-up pane.

Isometric 05 - Water Distribution System

Figure 35 Isometric 05 - Water Distribution System

Water is distributed from six reservoirs to 26 outlet points within a township.

The flow demands at the outlet points range from 0.3 MGD (US) up to 2.25 MGD (US).

Four centrifugal pumps are used to assist the supply from some of the reservoirs.

Pipe Flow Expert will calculate the flow rate in each pipe and the pressure at each node.

If a burst occurred in the system, the pipe would be 'closed off' while repairs occurred. The operation of the network in this situation can be modeled by 'closing' the burst pipe on the drawing.

Re-calculation of the system will instantly give the operating flow rates and pressure conditions throughout the system.

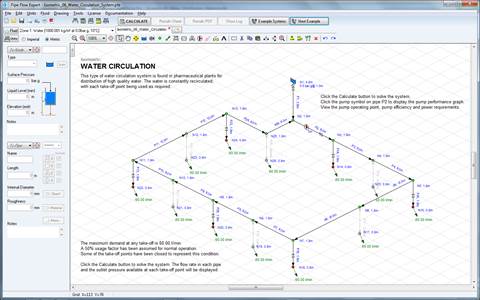

Isometric 06 - Water Circulation System

Figure 36 Isometric 06 - Water Circulation System

This type of water circulation system is found in pharmaceutical plants for distribution of high quality water. The water is constantly re-circulated, with each take-off point being used as required.

The maximum demand at any take-off is 60.00 l/min. A 50% usage factor has been assumed for normal operation. Some of the take-off points have been closed to represent this condition.

Click the Calculate button to solve the system. The flow rate in each pipe and the outlet pressure available at each take-off point will be displayed.

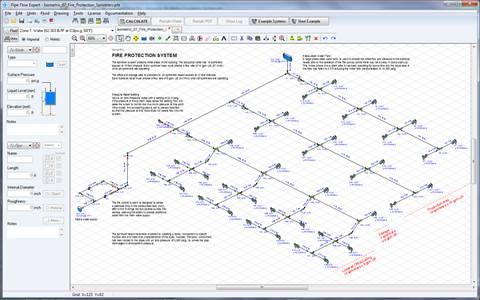

Isometric 07 - Fire Protection Sprinklers

Figure 37 Isometric 07 - Fire Protection Sprinklers

The sprinkler system protects three areas of a building.

The production area has 16 sprinklers, spaced at 15 foot intervals. Each sprinkler head must provide a flow rate of 15 gpm US (57 l/min) when all sprinklers are operating.

The office and storage areas are protected by 20 sprinklers heads spaced at 10 foot intervals. Each sprinkler head must provide a flow rate of 9 gpm US (34 l/min) when all sprinklers are operating.

The sprinkler heads have been modelled by creating a 'spray' component to specify the flow rate and head loss characteristics of the spray nozzles. The 'spray' component has been added to the pipes with an 'end pressure' of 0.000 psig, i.e. where the pipe discharges to atmospheric pressure.

Isometric 08 - Fire Protection Water Mist

Figure 38 Isometric 08 - Fire Protection Water Mist

A warehouse 24m long x 18m wide is protected by a high pressure water mist fire protection system.

A total of 36 high pressure water mist nozzles are used. Each nozzle covers a 3m x 4m area.

The water mist nozzles are located at an elevation of 4.0m hence each nozzle must provide enough water to cover an area of 3m x 4m x 4m.

The spray volume required for this type of system is typically 0.08 - 0.10 l/min for each cubic meter to be protected.

The flow required from each nozzle is therefore 3 x 4 x 4 x 0.10 l/min = 4.8 l/min

This gives a minimum flow requirement of 36 x 4.8 l/min = 172.8 l/min.

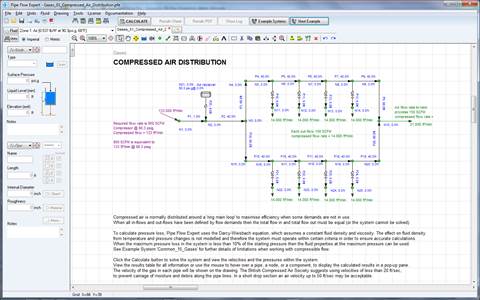

Gases 01 - Compressed Air Distribution

Figure 39 Gases 01 - Compressed Air Distribution

Compressed air is normally distributed around a 'ring main’ loop to maximize efficiency when some demands are not in use. When all in-flows and out-flows have been defined by flow demands then the total flow in and the total flow out must be equal (or the system cannot be solved).

To calculate pressure loss, Pipe Flow Expert uses the Darcy-Weisbach equation, which assumes a constant fluid density and viscosity. Any changes in fluid density caused by changes in temperature and pressure are not modelled and therefore the system must operate within certain criteria in order to ensure accurate calculations.

When the maximum pressure loss in the system is less than 10% of the starting pressure then the fluid properties at the starting pressure can be used. See Example System 'Common_15_Gases' for further details of limitations when working with compressible flow.

Click the Calculate button to solve the system and view the velocities and the pressures within the system. View the Results Sheet to see tabulated results or use the mouse to hover over a pipe, a node, or a component, to display the calculated results in a pop-up pane. The velocity of the gas in each pipe will be shown on the drawing.

The British Compressed Air Society suggests using velocities of less than 20 ft/sec, to prevent carriage of moisture and debris along the pipe lines. In a short drop section an air velocity up to 50 ft/sec may be acceptable.

Gases 02 - Compressed Air Zoned

Figure 40 Gases 02 - Compressed Air Zoned

This example uses different fluid zones to model a compressed air system which includes two lower pressure sub-systems. The lower pressure sections are supplied from the 'ring main' distribution system and are controlled by pressure reducing valves.

Note: All flow values are specified in mass flow units (kg/min). Mass flow values will be consistent throughout the model i.e. the mass flow exiting a pipe will be the same as the mass flow entering the pipe.

Actual volumetric flow rates will increase throughout the model, since as the pressure in the pipe reduces so the volume of gas will increase.

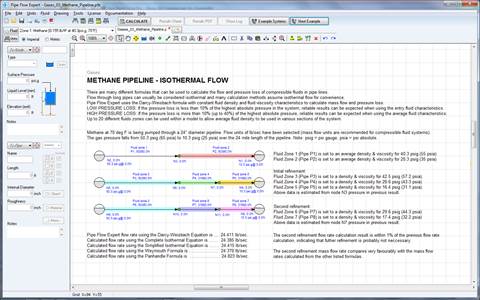

Gases 03 - Methane Pipeline

Figure 41 Gases 03 - Methane Pipeline

There are many different formulas that can be used to calculate the flow and pressure loss of compressible fluids in pipe lines. Flow through long pipes can usually be considered isothermal and many calculation methods assume isothermal flow for convenience.

Pipe Flow Expert uses the Darcy-Weisbach formula with constant fluid density and fluid viscosity characteristics to calculate mass flow and pressure loss.

LOW PRESSURE LOSS: If the pressure loss is less than 10% of the highest absolute pressure in the system, reliable results can be expected when using the entry fluid characteristics.

HIGH PRESSURE LOSS: If the pressure loss is more than 10% (up to 40%) of the highest absolute pressure, reliable results can be expected when using the average fluid characteristics.

Up to 20 different fluids zones can be used within a model to allow average fluid density to be used in various sections of the system.

Pipe Flow Expert flow rate using the Darcy-Weisbach Equation is ...24.411 lb/sec.

Calculated flow rate using the Complete Isothermal Equation is ......24.385 lb/sec.

Calculated flow rate using the Simplified Isothermal Equation is ......24.415 lb/sec.

Calculated flow rate using the Weymouth Formula is ......................24.370 lb/sec.

Calculated flow rate using the Panhandle Formula is .....................24.823 lb/sec.