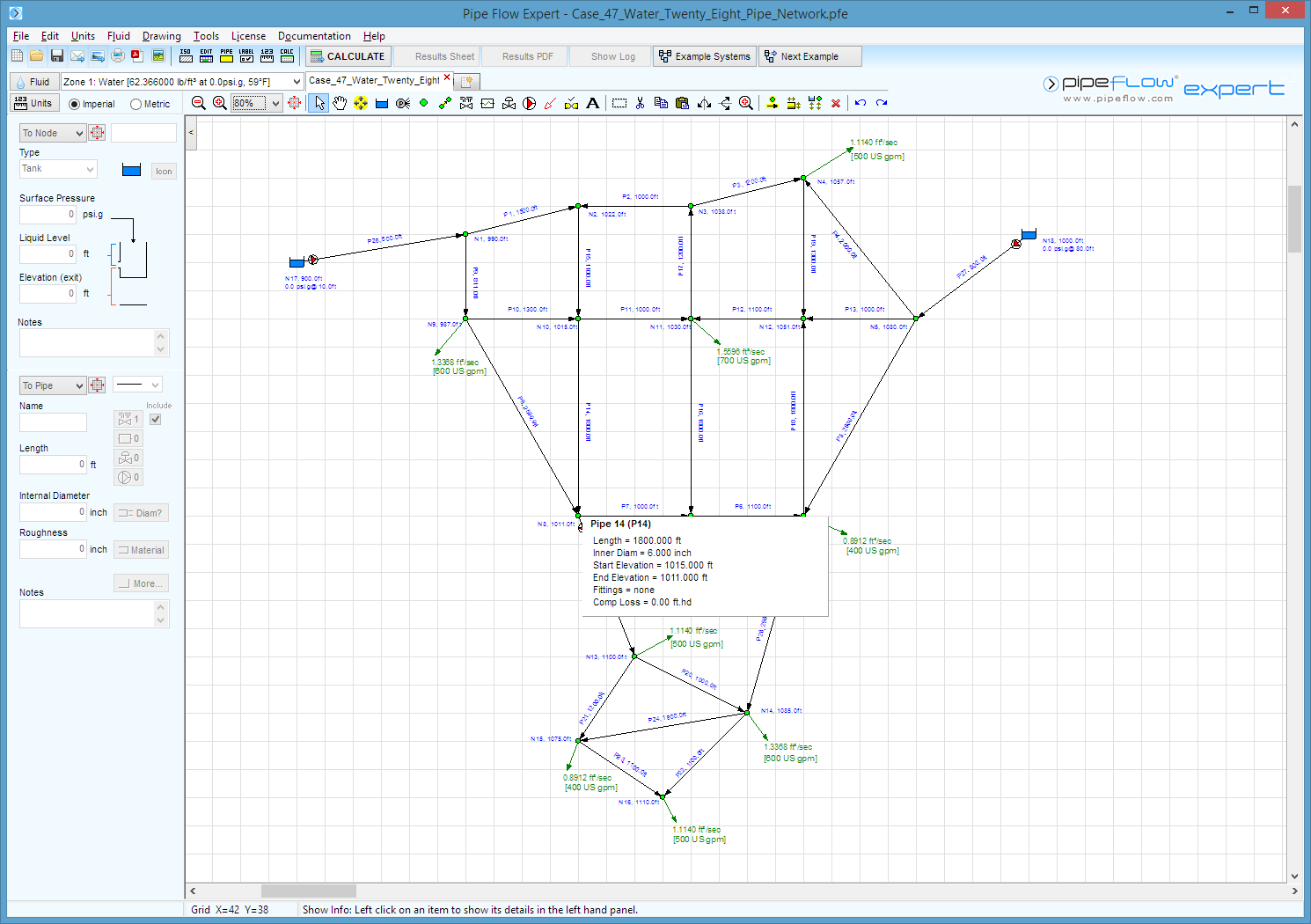

Case 47: Water – Twenty Eight Pipe Network - 3 Pumps

Reference: Analysis of Flow in Pipe Networks, 1976, Publisher Ann Arbor Science, Rowland W. Jeppson, Example problem 6 page 95 - 98

Pipe Flow Expert File: Case_47_Water_Twenty_Eight_Pipe_Network.pfe

Problem Description:

Water is supplied from two reservoirs to a twenty eight pipe network.

The pipes are connected at sixteen node points.

The network contains 3 pumps.

Out flows from the network occur at several node points.

Find the flow rate and head loss for each pipe.

Find the Hydraulic Grade Line at each node point.

Fluid Data: Water at 59° F (assumed).

Result Comparison:

● = Pipe Flow Expert reversed pipe direction and reported flow as positive

|

Pipe |

Published Flow (ft³/s) |

Pipe Flow Expert (ft³/s) |

|

Pipe |

Published Head Loss (ft) |

Pipe Flow Expert Head Loss (ft) |

|

P 1 |

2.94 |

2.7772 |

|

P 1 |

6.41 |

6.01 |

|

P 2 |

-1.76 |

● 1.6707 |

|

P 2 |

11.85 |

12.04 |

|

P 3 |

-0.54 |

● 0.5778 |

|

P 3 |

0.62 |

0.59 |

|

P 4 |

1.74 |

1.7883 |

|

P 4 |

9.10 |

8.68 |

|

P 5 |

0.88 |

0.8904 |

|

P 5 |

10.76 |

9.86 |

|

P 6 |

-2.55 |

● 2.4480 |

|

P 6 |

30.20 |

28.11 |

|

P 7 |

-3.35 |

● 3.2081 |

|

P 7 |

45.50 |

43.63 |

|

P 8 |

2.17 |

2.2590 |

|

P 8 |

51.10 |

54.53 |

|

P 9 |

3.07 |

3.2297 |

|

P 9 |

43.90 |

35.86 |

|

P 10 |

-0.44 |

● 0.3661 |

|

P 10 |

7.92 |

3.59 |

|

P 11 |

-0.58 |

● 0.5495 |

|

P 11 |

9.90 |

6.06 |

|

P 12 |

0.64 |

0.6207 |

|

P 12 |

8.20 |

8.45 |

|

P 13 |

0.73 |

0.6720 |

|

P 13 |

9.38 |

8.97 |

|

P 14 |

1.32 |

1.2899 |

|

P 14 |

59.00 |

58.12 |

|

P 15 |

1.18 |

1.1065 |

|

P 15 |

29.60 |

26.25 |

|

P 16 |

0.80 |

0.7601 |

|

P 16 |

23.40 |

20.55 |

|

P 17 |

-2.29 |

● 2.2485 |

|

P 17 |

7.86 |

8.15 |

|

P 18 |

-0.17 |

● 0.1478 |

|

P 18 |

1.37 |

0.89 |

|

P 19 |

0.09 |

0.0965 |

|

P 19 |

0.28 |

0.29 |

|

P 20 |

3.27 |

3.0903 |

|

P 20 |

37.60 |

40.51 |

|

P 21 |

2.45 |

2.5527 |

|

P 21 |

30.70 |

33.32 |

|

P 22 |

-0.04 |

● 0.1040 |

|

P 22 |

0.01 |

0.07 |

|

P 23 |

1.15 |

1.2180 |

|

P 23 |

6.90 |

7.13 |

|

P 24 |

-0.41 |

● 0.4435 |

|

P 24 |

6.91 |

7.20 |

|

P 25 |

6.84 |

6.7570 |

|

P 25 |

30.60 |

34.60 |

|

P 26 |

6.01 |

6.0069 |

|

P 26 |

0.91 |

0.65 |

|

P 27 |

3.35 |

3.3507 |

|

P 27 |

0.31 |

0.21 |

|

P 28 |

-2.39 |

● 2.3010 |

|

P 28 |

8.43 |

6.94 |

|

Node |

Published Press. (ft hd) |

Pipe Flow Expert (psig) |

|

Node |

Published HGL. (ft) |

Pipe Flow Expert HGL (ft) |

|

N1 |

not published |

162.6073 |

|

N1 |

1365 |

1365.45 |

|

N2 |

not published |

146.1446 |

|

N2 |

1359 |

1359.44 |

|

N3 |

not published |

133.9999 |

|

N3 |

1347 |

1347.40 |

|

N4 |

not published |

126.0271 |

|

N4 |

1348 |

1347.99 |

|

N5 |

not published |

119.8254 |

|

N5 |

1357 |

1356.67 |

|

N6 |

not published |

119.8479 |

|

N6 |

1346 |

1346.81 |

|

N7 |

not published |

127.2001 |

|

N7 |

1316 |

1318.70 |

|

N8 |

not published |

114.3679 |

|

N8 |

1270 |

1275.07 |

|

N9 |

not published |

148.3774 |

|

N9 |

1321 |

1329.60 |

|

N10 |

not published |

137.8059 |

|

N10 |

1329 |

1333.19 |

|

N11 |

not published |

133.9343 |

|

N11 |

1339 |

1339.25 |

|

N12 |

not published |

128.4999 |

|

N12 |

1347 |

1347.70 |

|

N13 |

not published |

127.4462 |

|

N13 |

1392 |

1394.27 |

|

N14 |

not published |

116.3962 |

|

N14 |

1354 |

1353.75 |

|

N15 |

not published |

123.8450 |

|

N15 |

1361 |

1360.95 |

|

N16 |

not published |

105.5984 |

|

N16 |

1354 |

1353.82 |

Commentary:

The published HGL data and the calculated results compare well.

The reference text uses the Hazen Williams method with a linear approximation to calculate head losses.

Pipe Flow Expert uses the more accurate Darcy-Weisbach equation and converges to within a pressure balance tolerance of 0.000145 psi.

The reference text indicates that the flow direction in a pipe is opposite to the direction shown on the schematic diagram by reporting the flow as negative value.

Pipe Flow Expert reversed the flow direction of the pipes indicated with ‘●’ automatically, and reported the flow rates in these pipes as a positive value.

The correlation of the HGL values is good, indicating that the calculated pressures at the nodes must be similar to un-published pressures obtained in the reference calculation.

There are differences in the flow rate and head loss calculations for each pipe.

Although the flow and head loss results may not agree to the normal expected accuracy, it will be noted that the results are around the same order of magnitude for the vast majority of the pipes.

The flow and head loss differences are due to errors produced by the Hazen Williams empirical approximation formula, used to produce the reference text results.

The Hazen Williams formula uses an arbitrary factor ‘C’ to estimate the head loss based on a particular flow rate.

The same ‘C’ factor is used for pipes P1 and P2, but when comparing the published results from these pipes it can be seen that the fluid velocities are 3.743 ft/sec and 5.042 ft/sec respectively.

The relative roughness factors are 0.0010 and 0.0015 respectively.

Given these comparisons it is obvious that these pipes cannot have the same friction factor.

Hence the use of the same ‘C’ factor will produce a degree of error in the published flow and head loss calculations.