Pipe Flow Expert Software Technical Videos

This page contains a set of technical training videos that explain and demonstrate how to use the Pipe Flow Expert software to calculate fluid flow rates, calculate pressure losses, calculate pump head requirements and check the overall operating performance of your pipe system.

This page contains a set of technical training videos that explain and demonstrate how to use the Pipe Flow Expert software to calculate fluid flow rates, calculate pressure losses, calculate pump head requirements and check the overall operating performance of your pipe system.

These training videos demonstrate how to use the Pipe Flow Expert Software to model different items.

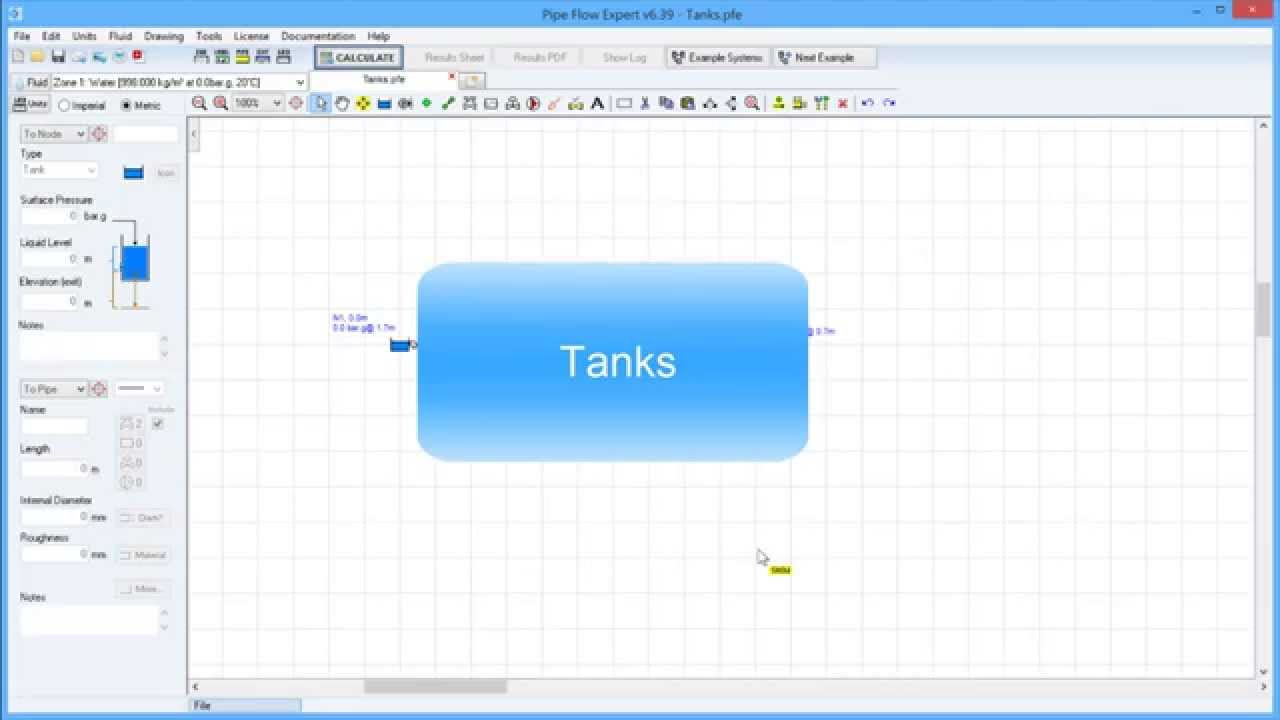

Pipe Flow Expert - Tanks

Pipe Flow Expert - Tanks

Pipe Flow Expert - Tanks

Pipe Flow Expert Software Demonstration of modeling fluid flow between two tanks with different levels of fluid.

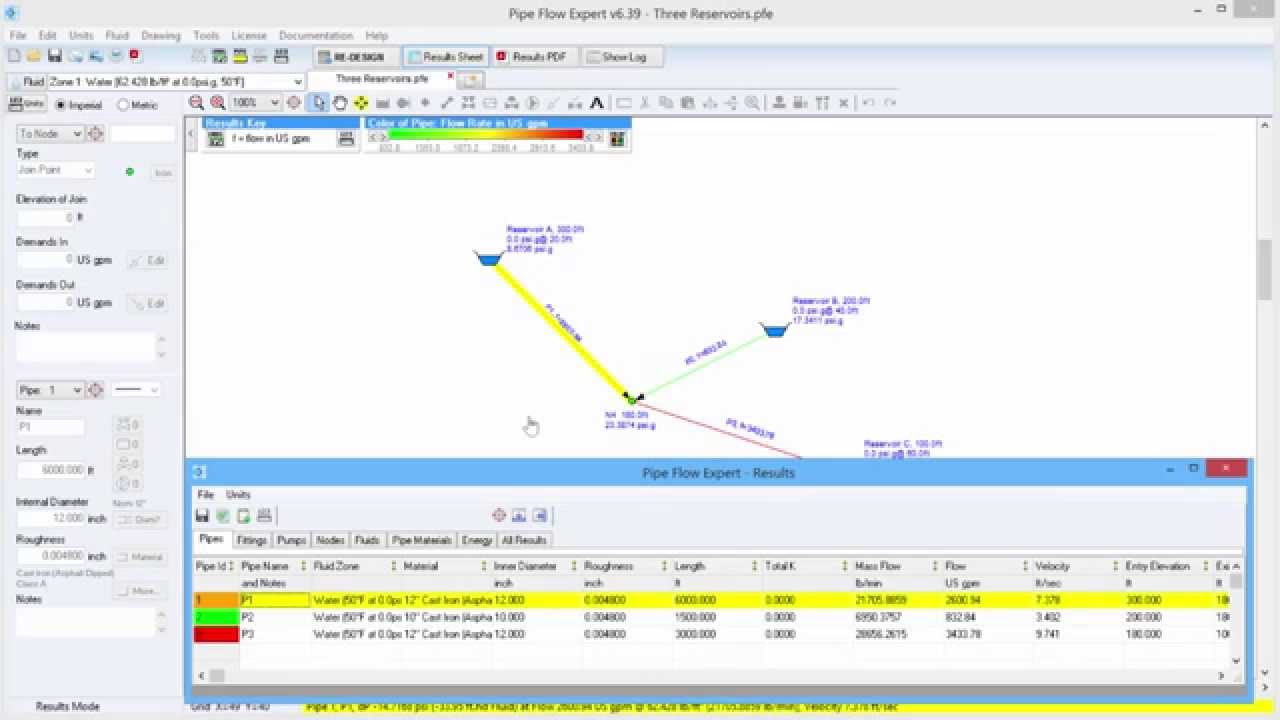

Pipe Flow Expert - Solving the Three Reservoirs Problem

Pipe Flow Expert - Solving the Three Reservoirs Problem

Modelling and solving the classic Three Reservoirs problem using Pipe Flow Expert.

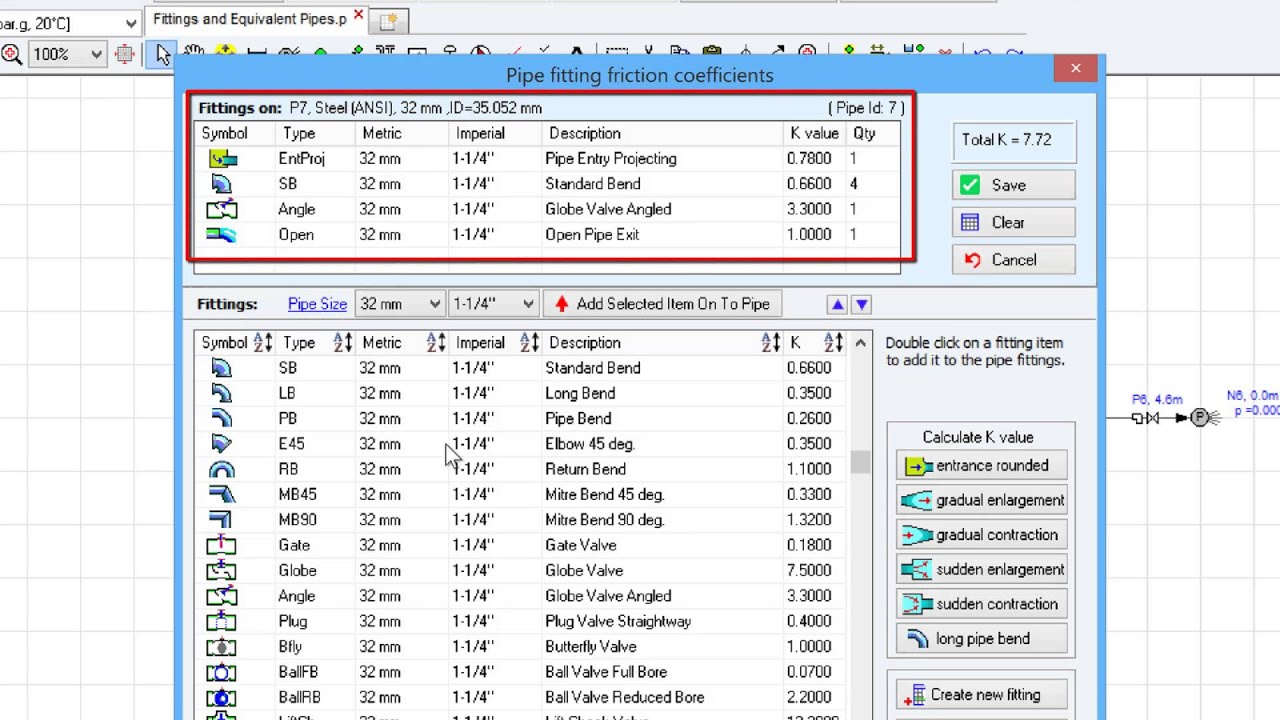

Pipe Flow Expert - Fittings

Pipe Flow Expert - Equivalent Pipes and Fittings

Pipe Flow Expert - Equivalent Pipes and Fittings

Modeling flow in a series of pipes and fittings as an equivalent single pipe with multiple fittings.

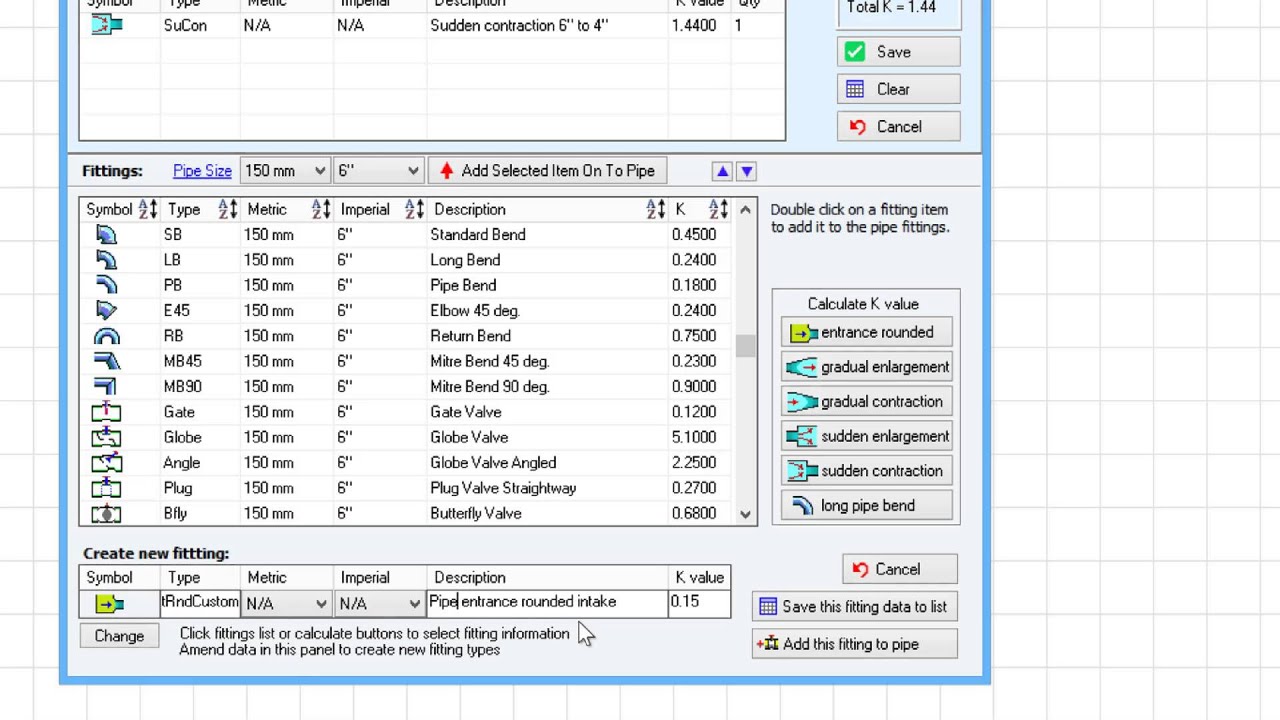

Pipe Flow Expert - Contractions and Enlargements

Pipe Flow Expert - Contractions and Enlargements

Demonstration of how to model contractions and enlargement fittings using Pipe Flow Expert.

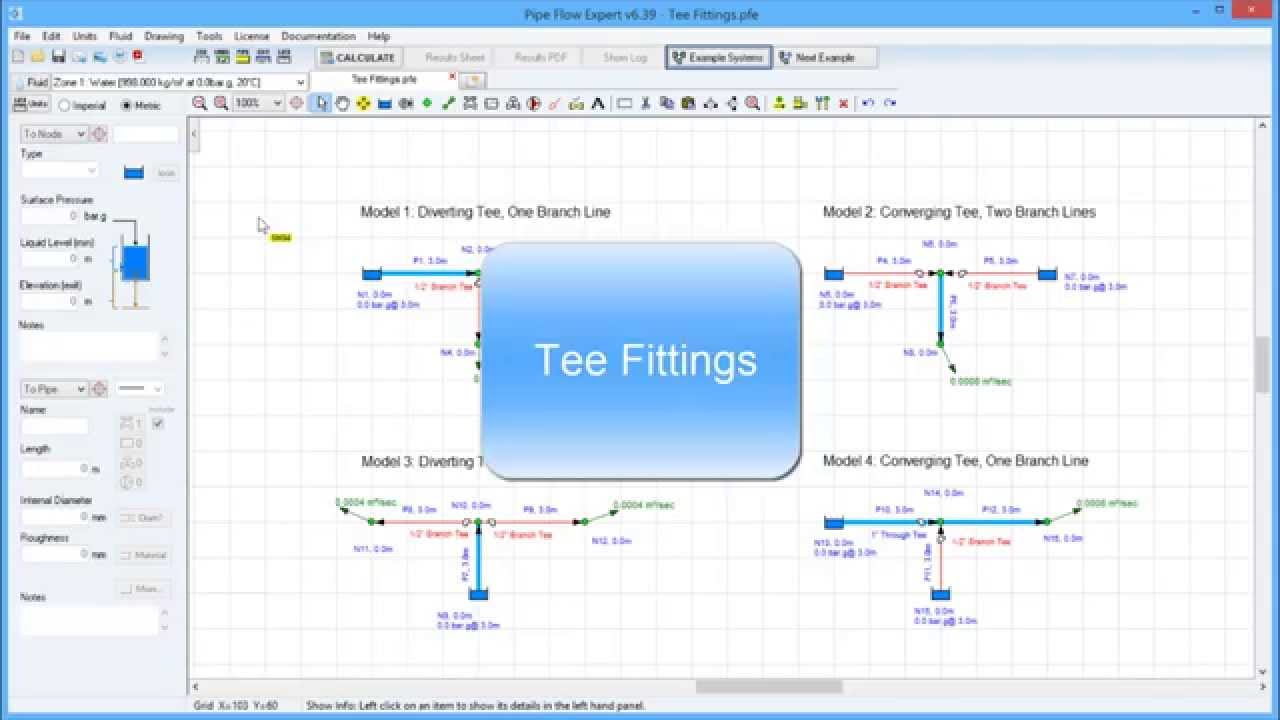

Pipe Flow Expert - Tee Fittings

Pipe Flow Expert - Tee Fittings

Modeling flow through branching pipe system with through tees and branch tees.

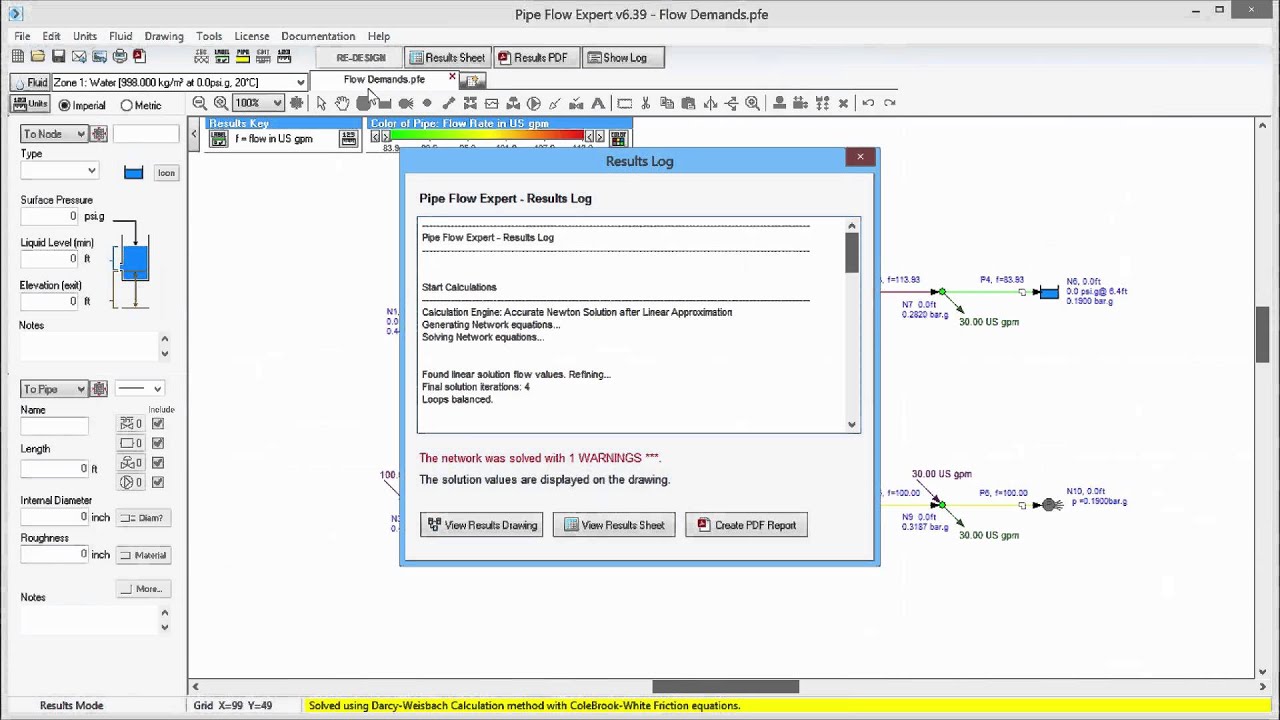

Pipe Flow Expert - Flow Demands

Pipe Flow Expert - Flow Demands

Pipe Flow Expert - Flow Demands

Modeling flow demands at nodes, to represent in-flow and out-flow from the system, using Pipe Flow Expert.

Pipe Flow Expert - Pumps

Pipe Flow Expert - Basic Pump Modeling

Pipe Flow Expert - Basic Pump Modeling

Adding a pump in a pipe system: as a fixed flow pump (where the software calculates the pump head required), or as a fixed head [pressure increase] pump (where the software calculates the flow rate that will occur), or as a fixed speed pump that operates on a flow versus head performance curve.

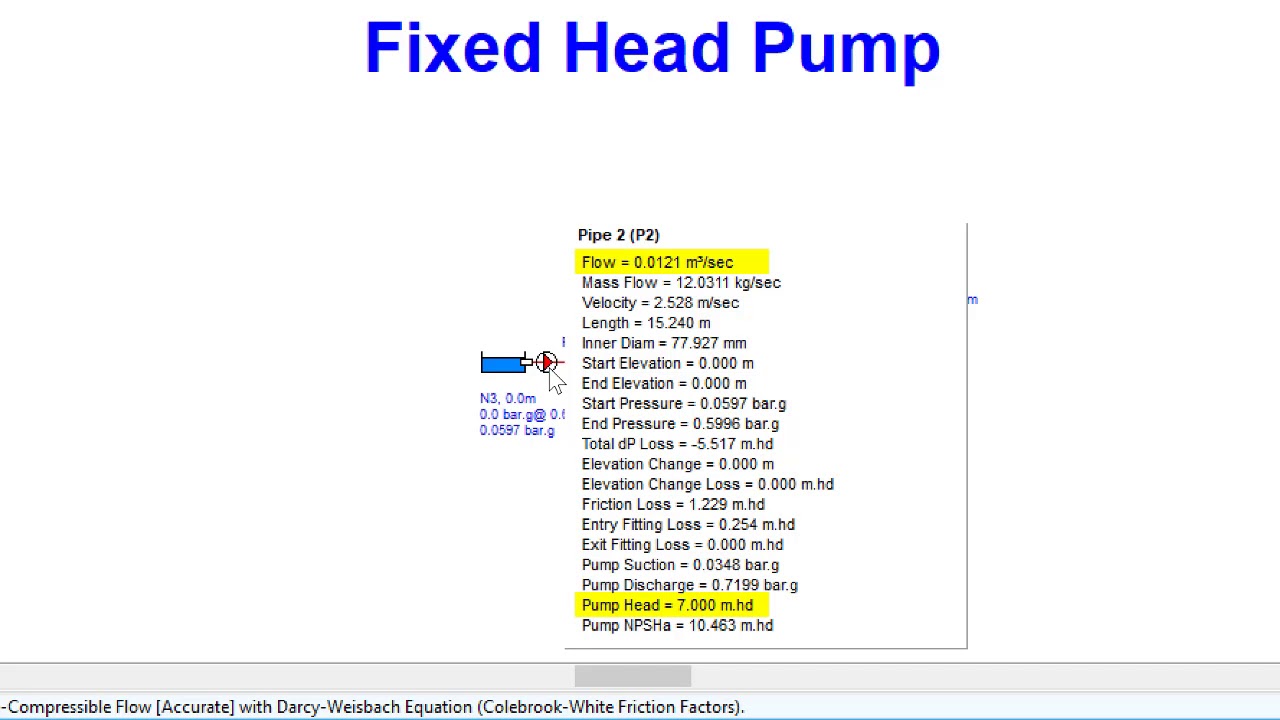

Pipe Flow Expert - Pump with Fixed Head Increase

Pipe Flow Expert - Pump with Fixed Head Increase

Demonstrates how to add a pump with a fixed head increase in a pipe system modeled using the Pipe Flow Expert software, so that the system can be calculated and solved to find the resulting flow rate.

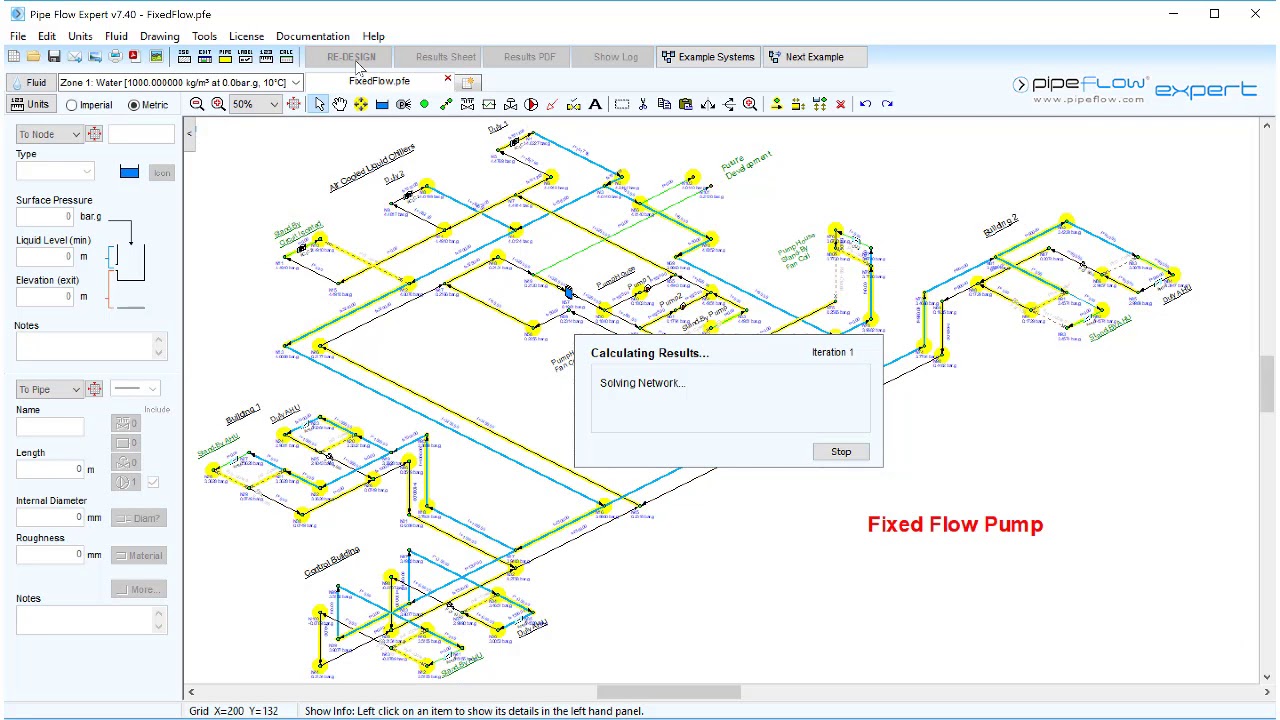

Pipe Flow Expert - Pump with Fixed Flow Rate

Pipe Flow Expert - Pump with Fixed Flow Rate

This video shows how to add a pump with a specified fixed flow rate in a model of piping system. The Pipe Flow Expert software then calculates the pump head required in order to achieve the given flow rate, when considering all of the other flows and pressures throughout the system.

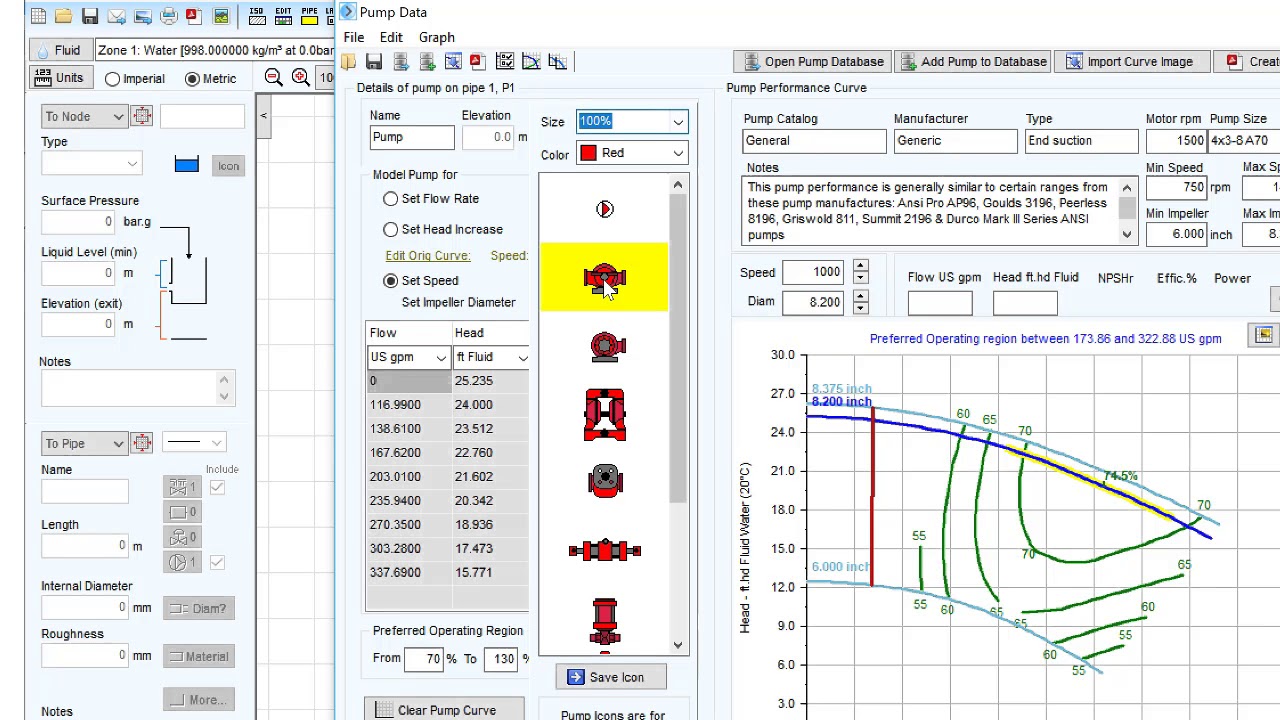

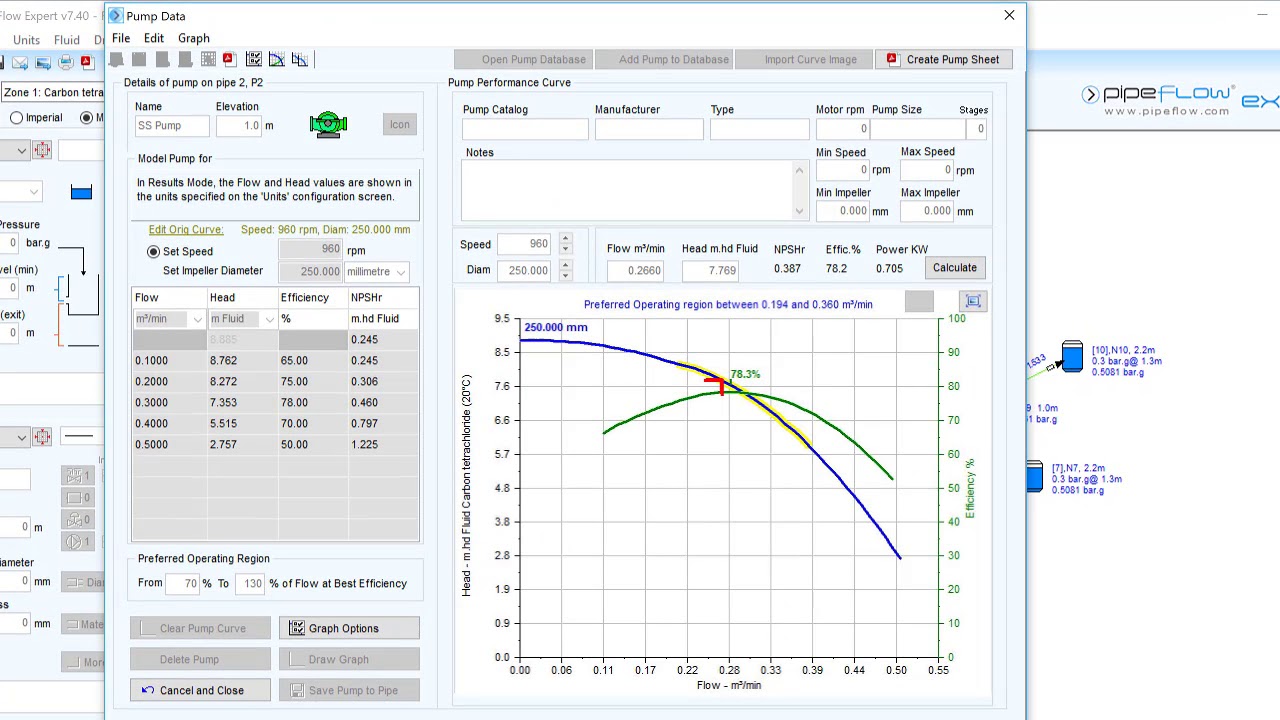

Pipe Flow Expert - Pump with Flow versus Head Curve

Pipe Flow Expert - Pump with Flow versus Head Curve

How to add a pump with a flow versus head curve in a model of a pipe system. The Pipe Flow Expert software solves the system and calculates the duty point, i.e. it calculates and shows the operating point on the pump curve, giving the flow rate and pump head that will occur when the system is up and running.

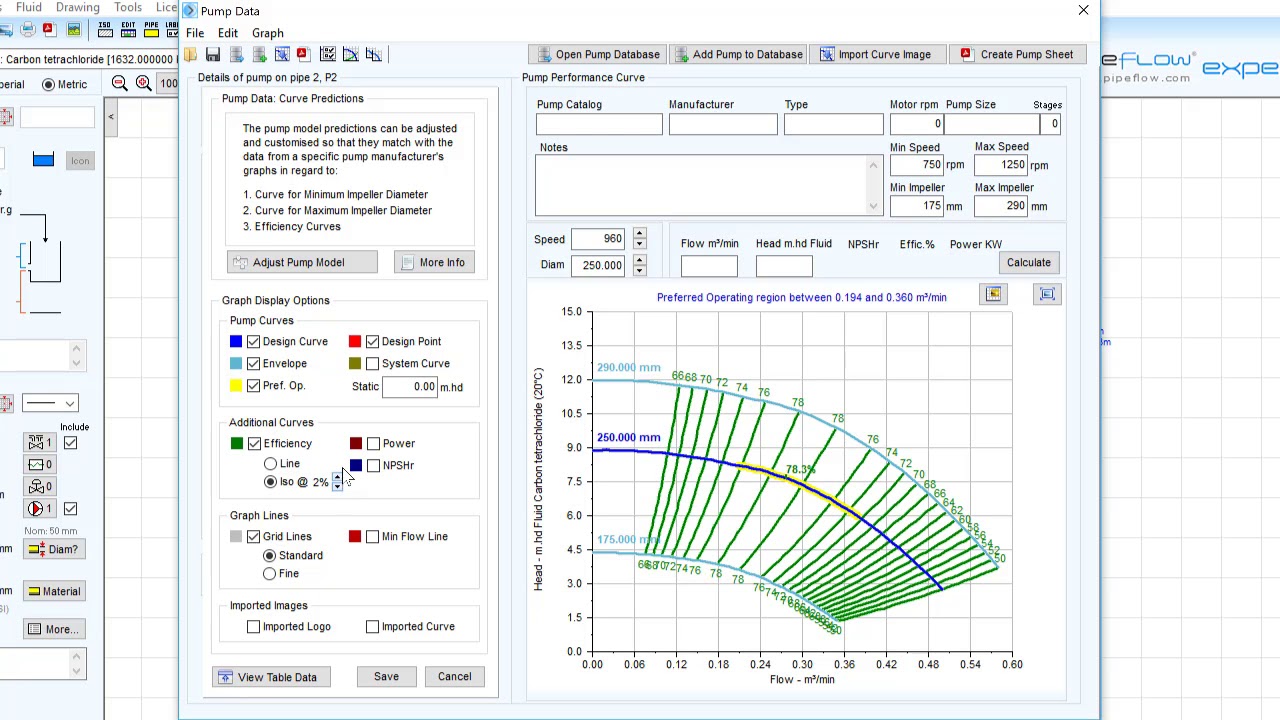

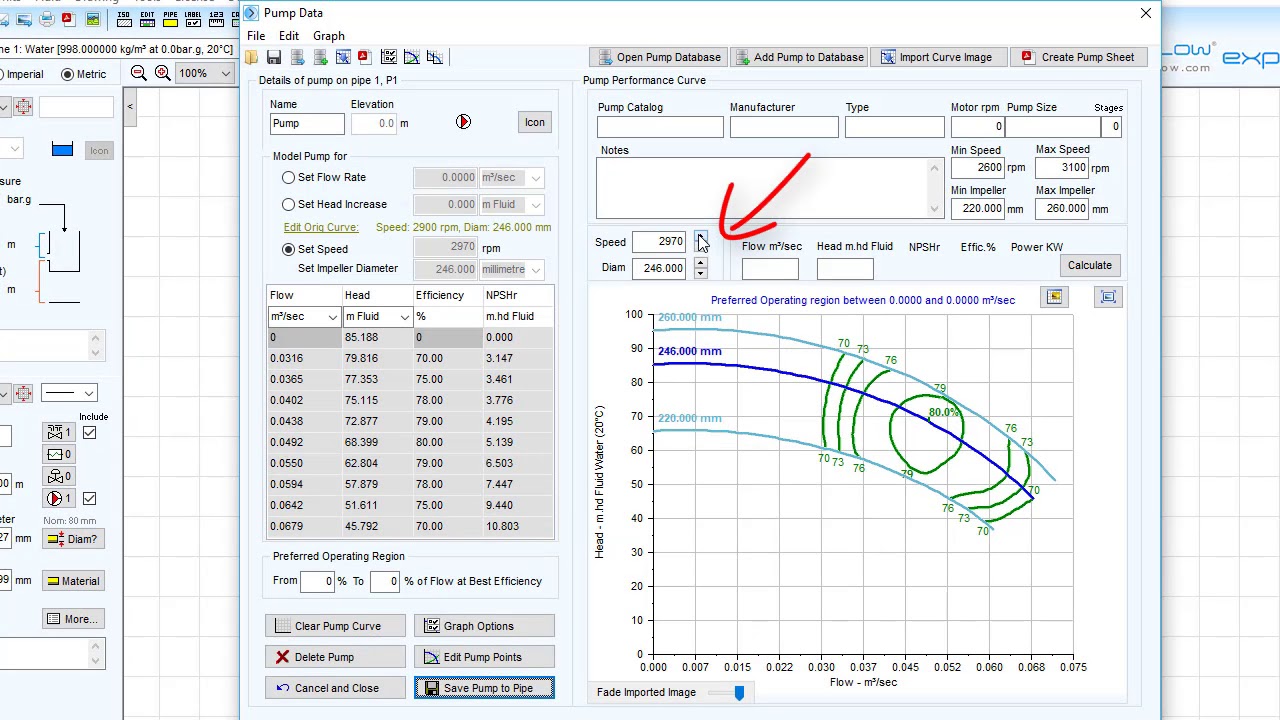

Pipe Flow Expert - Pump Predicted Graph across Speeds & Impellers

Pipe Flow Expert - Pump Predicted Graph across Speeds & Impellers

How to define a single pump curve that can then be used to predict the pump performance graph across a range of speeds and impeller sizes. The Pipe Flow Expert software also allows further customization of the pump graph predictions to match exactly against the pump graph provided by the pump manufacturer.

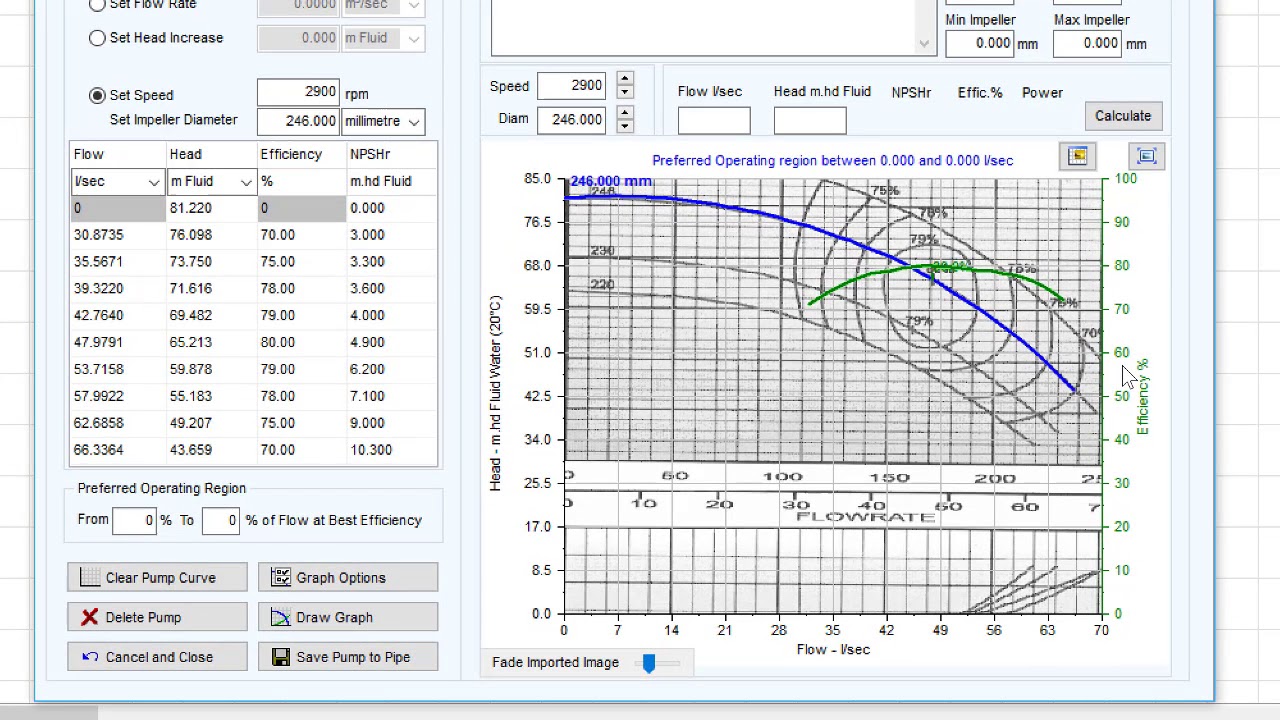

Pipe Flow Expert - Import Pump Curve Graph

Pipe Flow Expert - Import Pump Curve Graph

Import a pump graph in to the Pipe Flow Expert software. Load a photo or image of the pump curve and then trace over the curve to define the pump performance as a series of data points for the flow rate and pump head values.

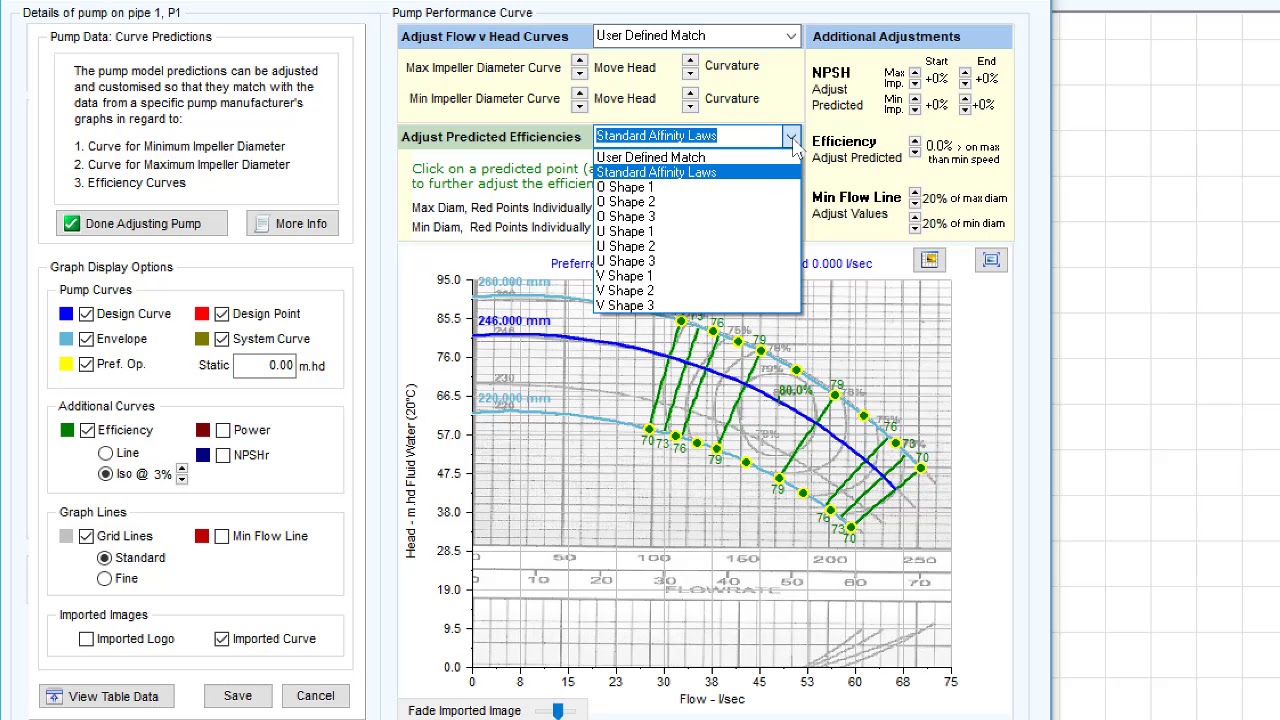

Pipe Flow Expert - Adjust Pump Curve Model

Pipe Flow Expert - Adjust Pump Curve Model

How to adjust the pump curve model within the Pipe Flow Expert software so that the pump performance data and efficiency lines exactly match the data as provided on a pump manufacturer's performance graph.

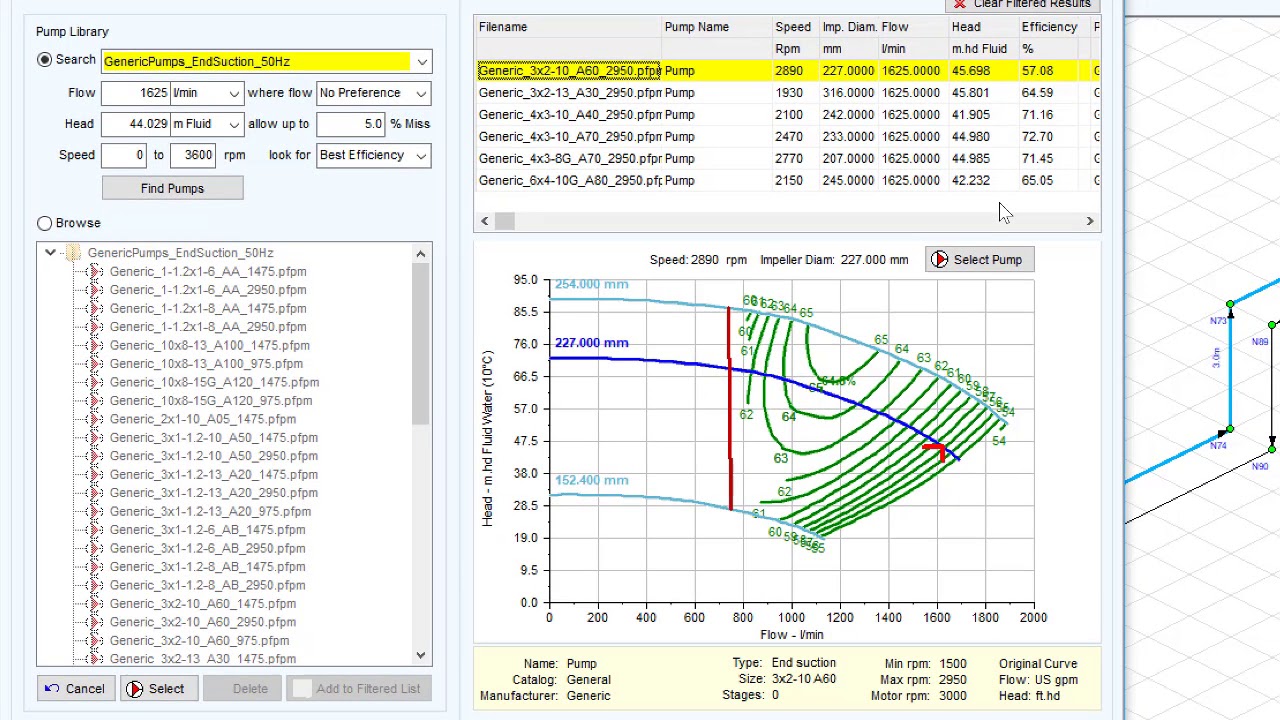

Pipe Flow Expert - Selecting a Pump

Pipe Flow Expert - Selecting a Pump

This video shows how to search the pump database within the Pipe Flow Expert software to select a pump that meets a required flow rate at a specific pump head.

Pipe Flow Expert - Pump Speed and Impeller Size Changes

Pipe Flow Expert - Pump Speed and Impeller Size Changes

Calculate the effect on flow rate and pump head requirements in a pipe system when the pump speed and impeller size are changed.

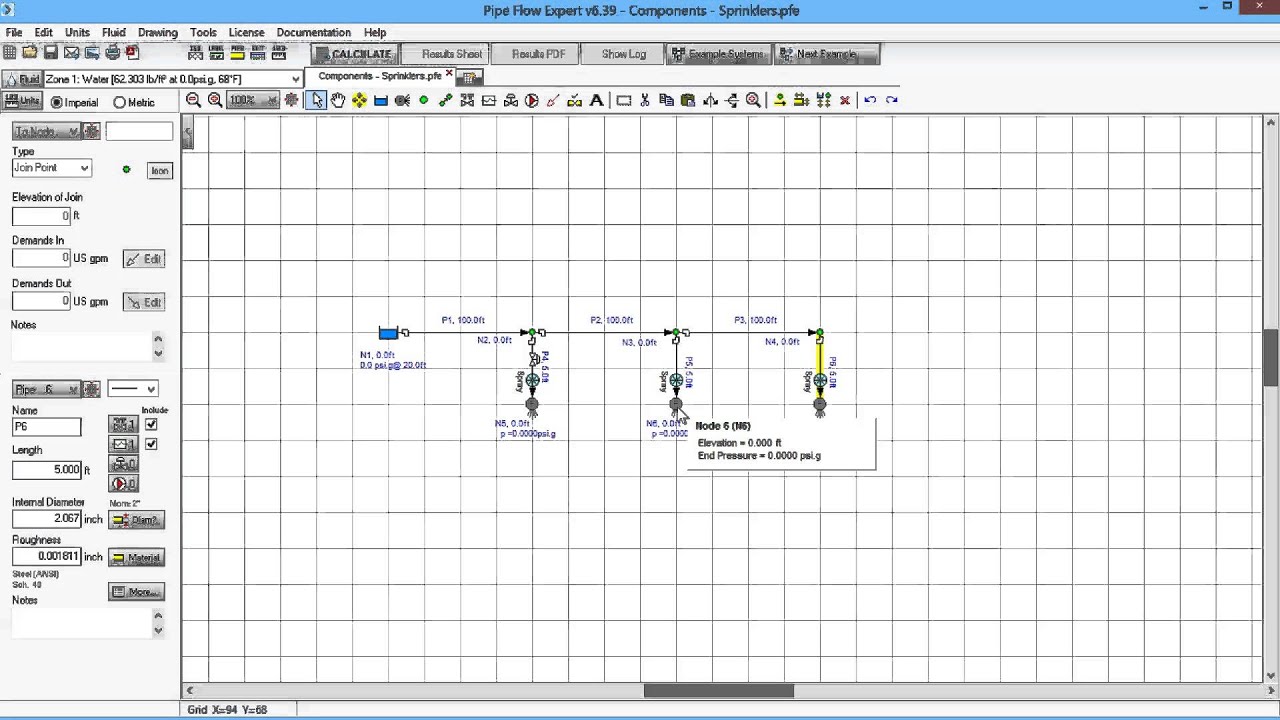

Pipe Flow Expert - Components

Pipe Flow Expert - Modeling Sprinklers

Pipe Flow Expert - Modeling Sprinklers

Demonstration of how to model a sprinkler within Pipe Flow Expert, using a component and an end pressure.

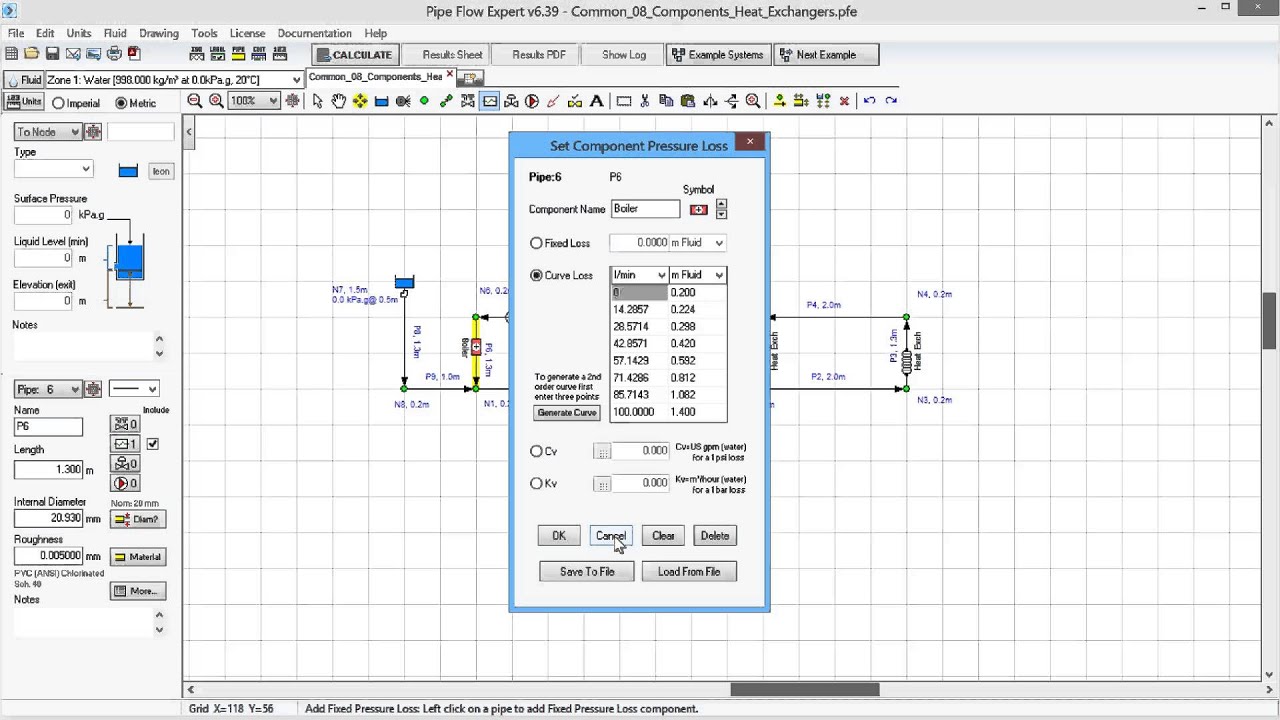

Pipe Flow Expert - Heat Exchangers

Pipe Flow Expert - Heat Exchangers

Demonstration of how Pipe Flow Expert can model heat exchangers, boilers, or any item where the loss characteristics are known.

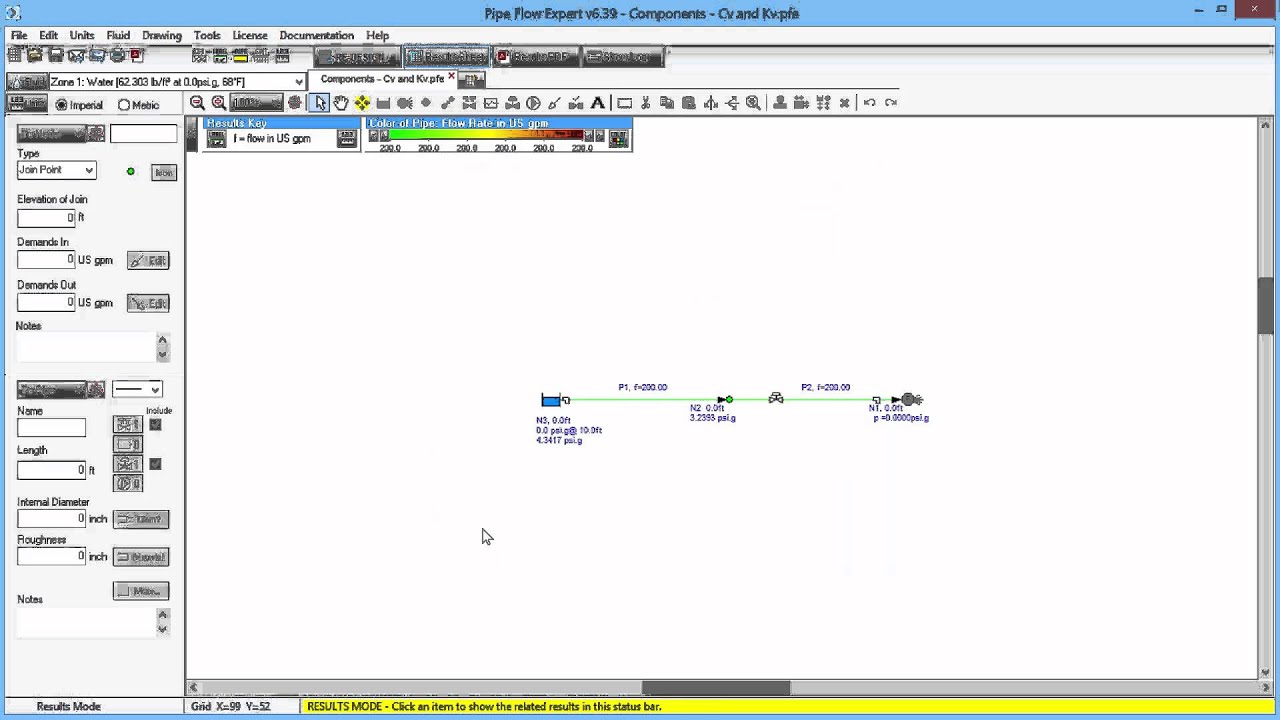

Pipe Flow Expert - Cv And Kv Values

Pipe Flow Expert - Cv And Kv Values

How to use Pipe Flow Expert to calculate a Cv or Kv value for a valve, modelled as a component, in order to achieve a specific flow rate and pressure loss.

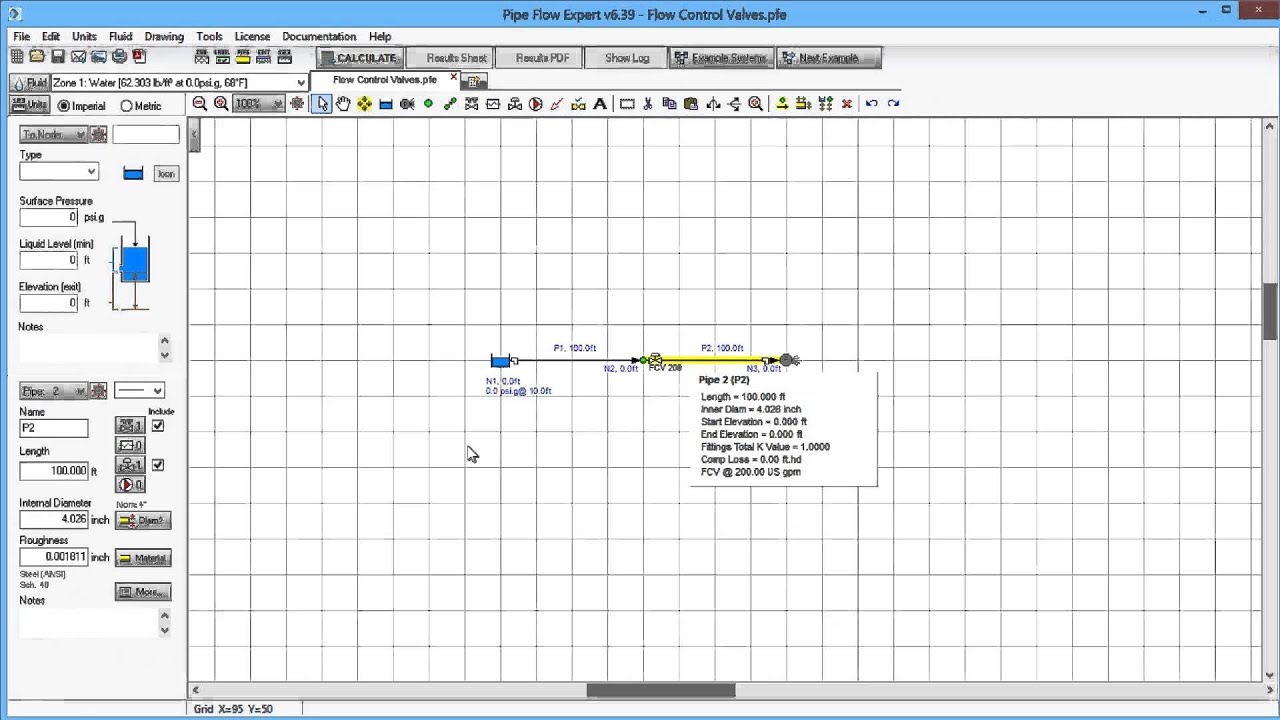

Pipe Flow Expert - Flow Control Valves

Pipe Flow Expert - Flow Control Valves

Pipe Flow Expert - Flow Control Valves

Flow control valve modeling within Pipe Flow Expert software, illustrating the effect on the flow rate and pressure calculations.

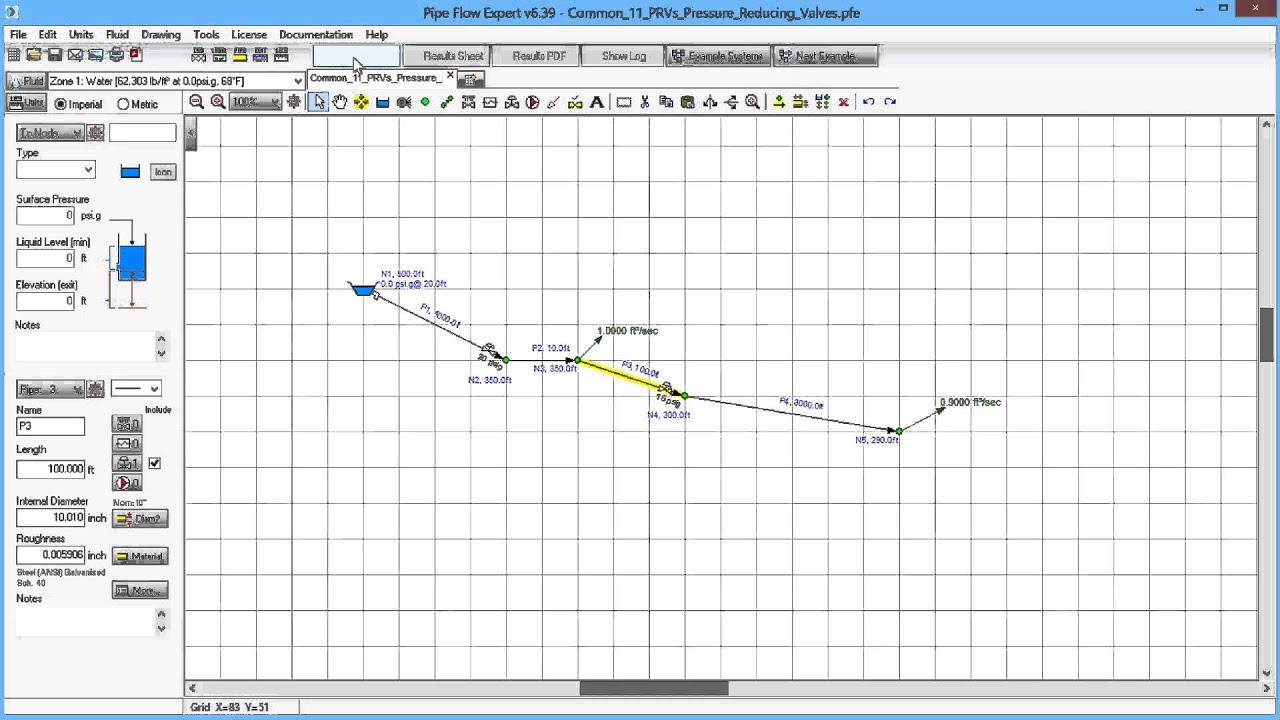

Pipe Flow Expert - Pressure Reducing Valves

Pipe Flow Expert - Pressure Reducing Valves

Pipe Flow Expert - Pressure Reducing Valves

Pressure reducing valve modeling within Pipe Flow Expert software, illustrating their effect on the flow rate and pressure calculations.

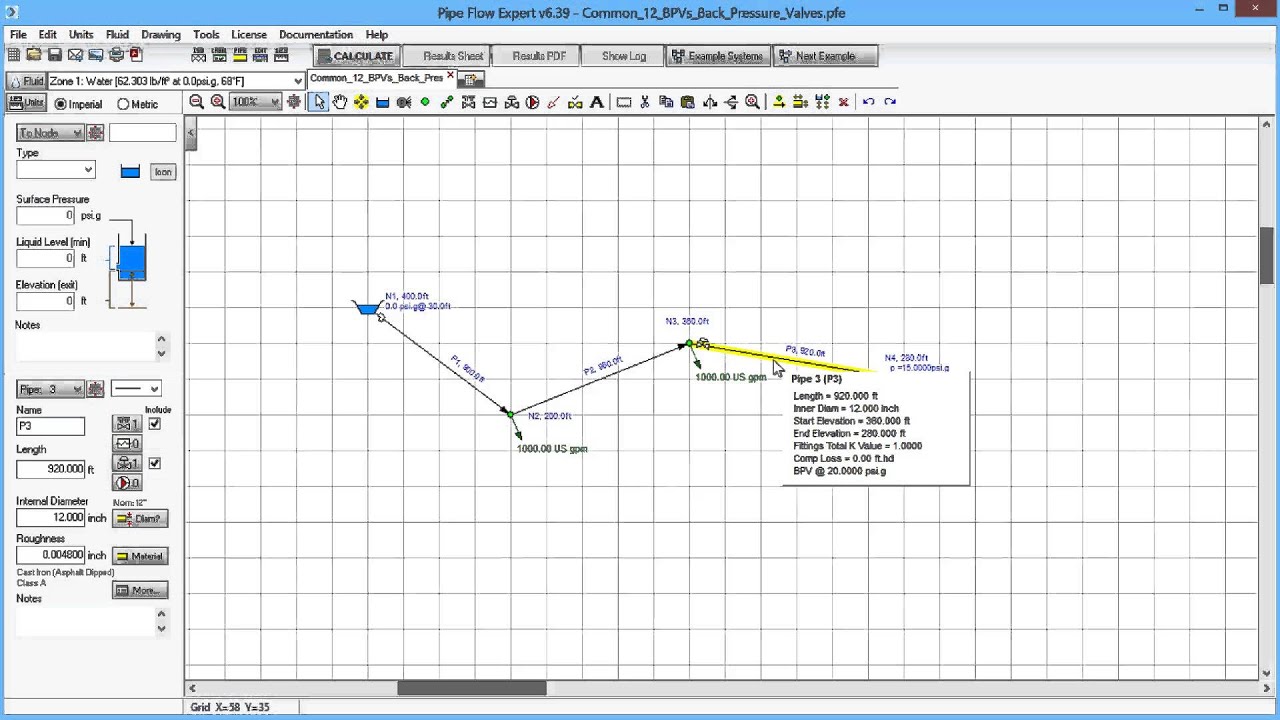

Pipe Flow Expert - Back Pressure Valves

Pipe Flow Expert - Back Pressure Valves

Pipe Flow Expert - Back Pressure Valves

Back pressure valve modeling within Pipe Flow Expert software, illustrating their effect on the flow rate and pressure calculations.

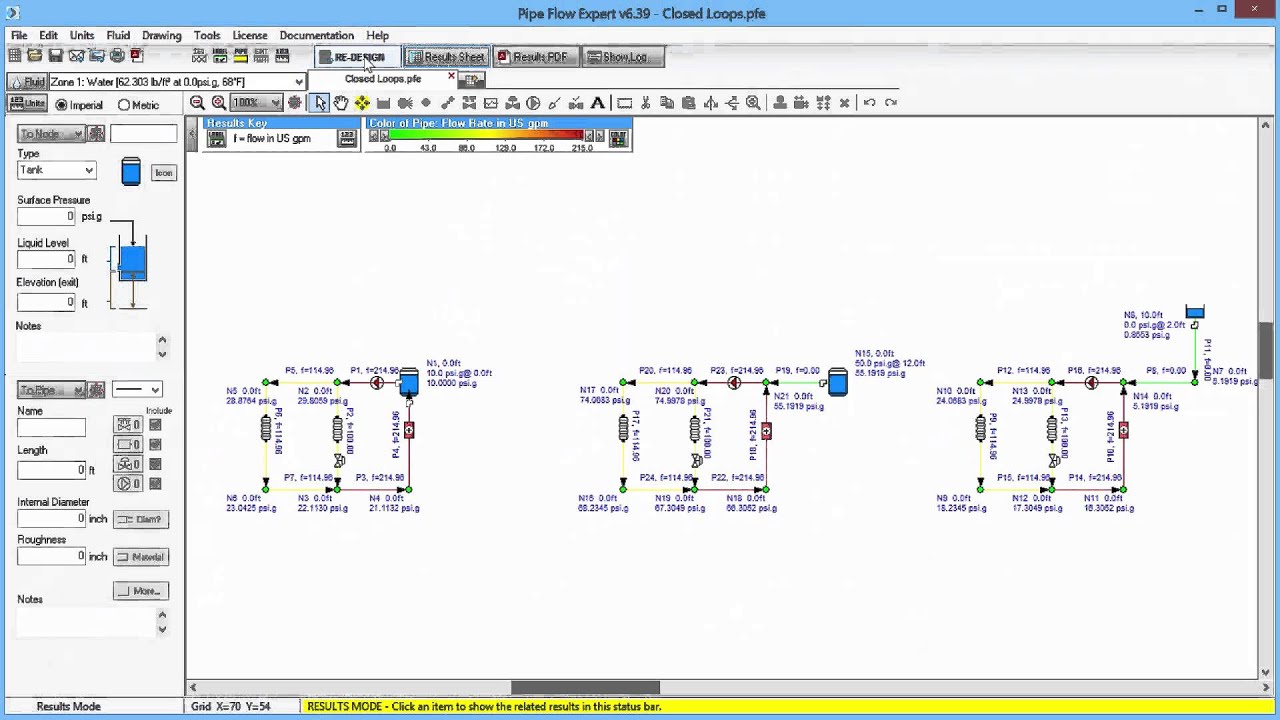

Pipe Flow Expert - Closed Loops

Pipe Flow Expert - Closed Loops

Pipe Flow Expert - Closed Loops

Modelling closed loop systems within Pipe Flow Expert, discussing the relationship between flow rate, pump head and reference pressure.

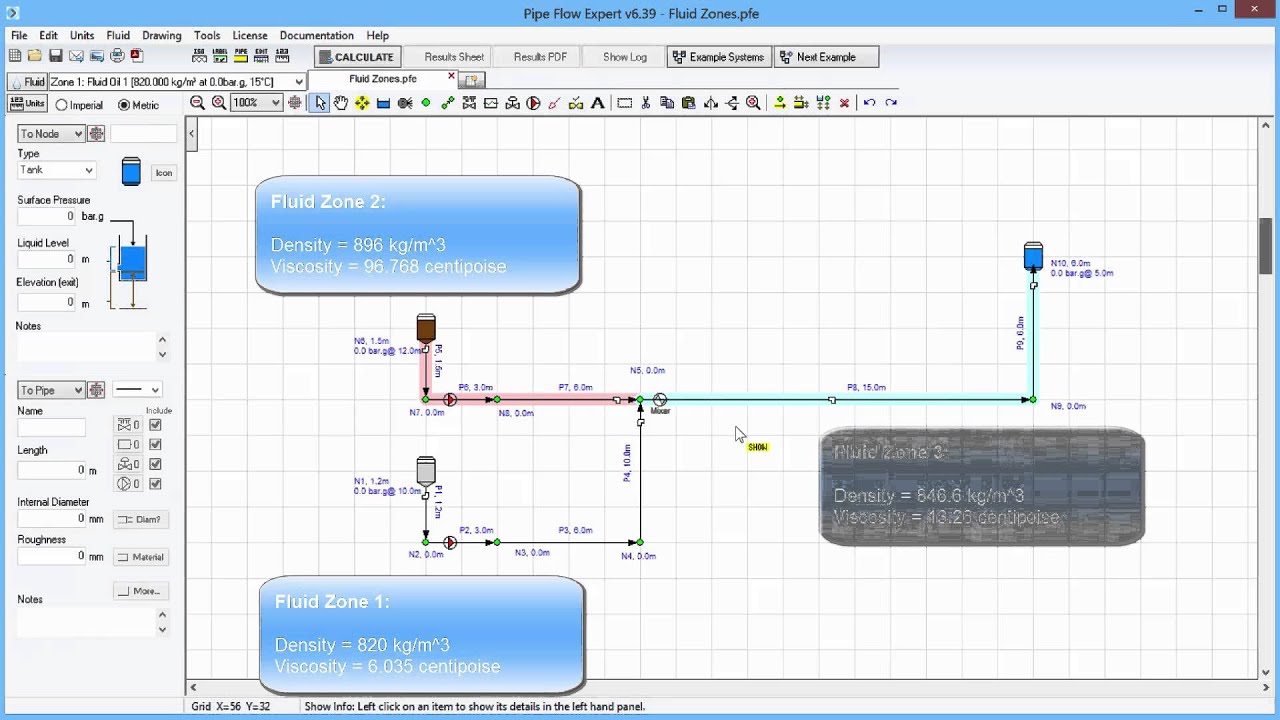

Pipe Flow Expert - Fluid Zones

Pipe Flow Expert - Fluid Zones

Pipe Flow Expert - Fluid Zones

Demonstration of how to model multiple fluids of different density and viscosity within a single Pipe Flow Expert model, using fluid zones.

Pipe Flow Expert - Energy Efficient Systems

Pipe Flow Expert - Energy Efficient Pipe Systems

Pipe Flow Expert - Energy Efficient Pipe Systems

Why are most pipe systems very energy inefficient? How can Pipe Flow Expert Software help engineers design energy efficient pipe systems?