Case 25: Ethanol - Laminar Flow

Reference: 2500 Solved Problems in Fluid Mechanics and Hydraulics, 1989, McGraw-Hill, Jack B. Evett, Ph. D., Cheng Liu, M.S., Page 207, Example problem 9.54

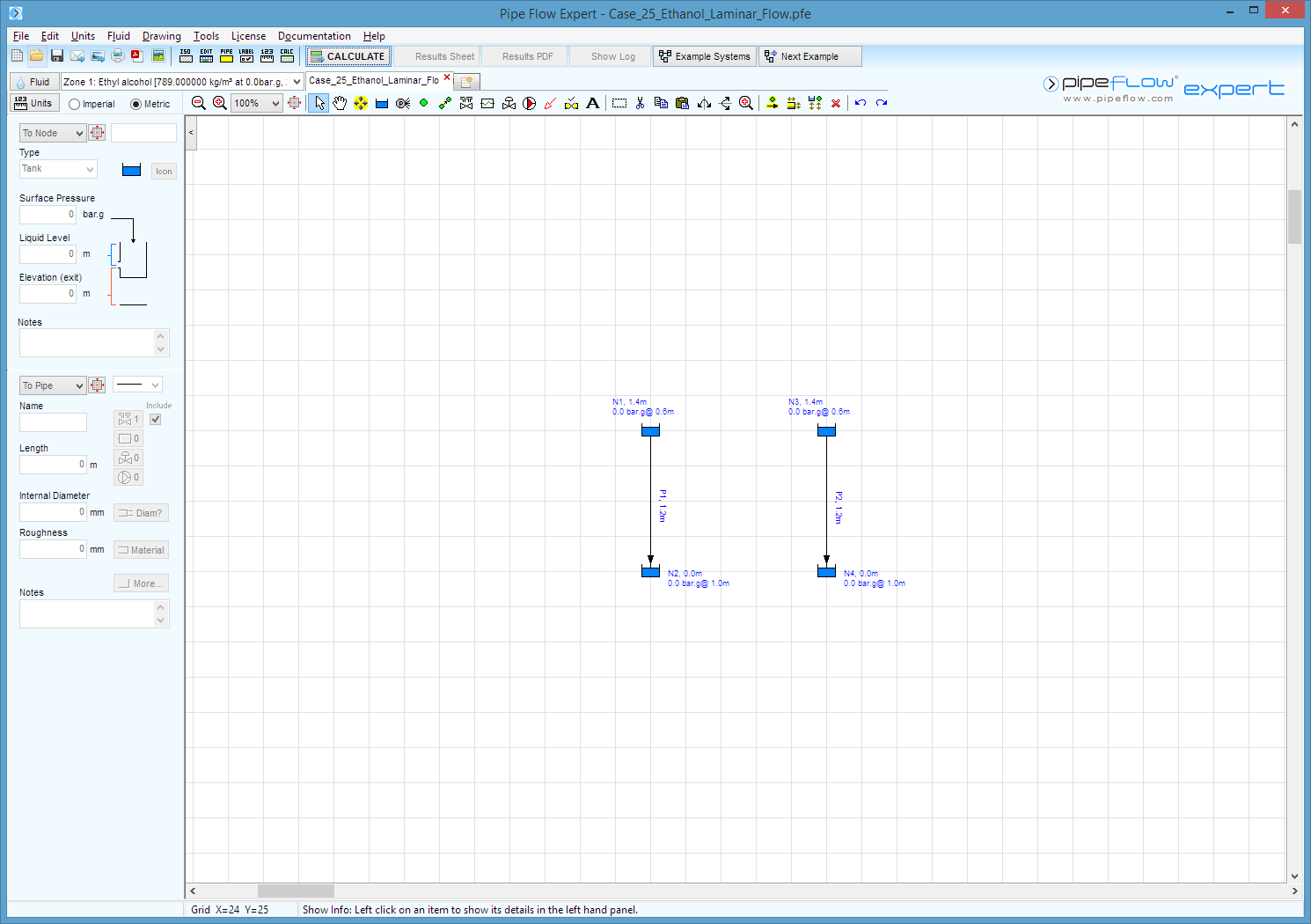

Pipe Flow Expert File: Case_25_Ethanol_Laminar_Flow.pfe

Problem Description:

Ethanol at 20°C is transferred from an upper tank to a lower tank via a 2 mm pipe.

The pipe is 1.2 m long, with 0.8 m of pipe dipping into the lower tank.

Calculate the flow rate between the tanks.

Fluid Data: Ethanol at 20°C (µ= 1.20 x 10-3 Pa · s), density = 788 kg/m3

Result Comparison:

|

Data Item |

Published data |

Pipe Flow Expert |

|

Flow from upper tank (l/hr) – Pipe 1 |

7.59 |

7.60 |

|

Flow from upper tank (l/hr) – Pipe 2 |

7.59 |

7.60 |

Commentary:

The published data and the calculated results compare well.

The published text does not list an inner roughness for the pipe.

The flow in this problem is laminar, so the friction factor is independent of the inner roughness of the pipe.

The calculated Reynolds number of 883 indicates that the flow type is well within the laminar flow range.

Two pipes with different inner roughness values (0.046000 mm and 0.000001 mm) were used in the Pipe Flow Expert model to ensure that the variation in the inner roughness of the pipe did not affect the flow rate calculation.