Case 31: Water – Flow Through Reduced Port Ball Valve

Reference: Flow of Fluids – Technical Paper No 410, 1988, Crane Co. Page 4-3, Example 4-6.

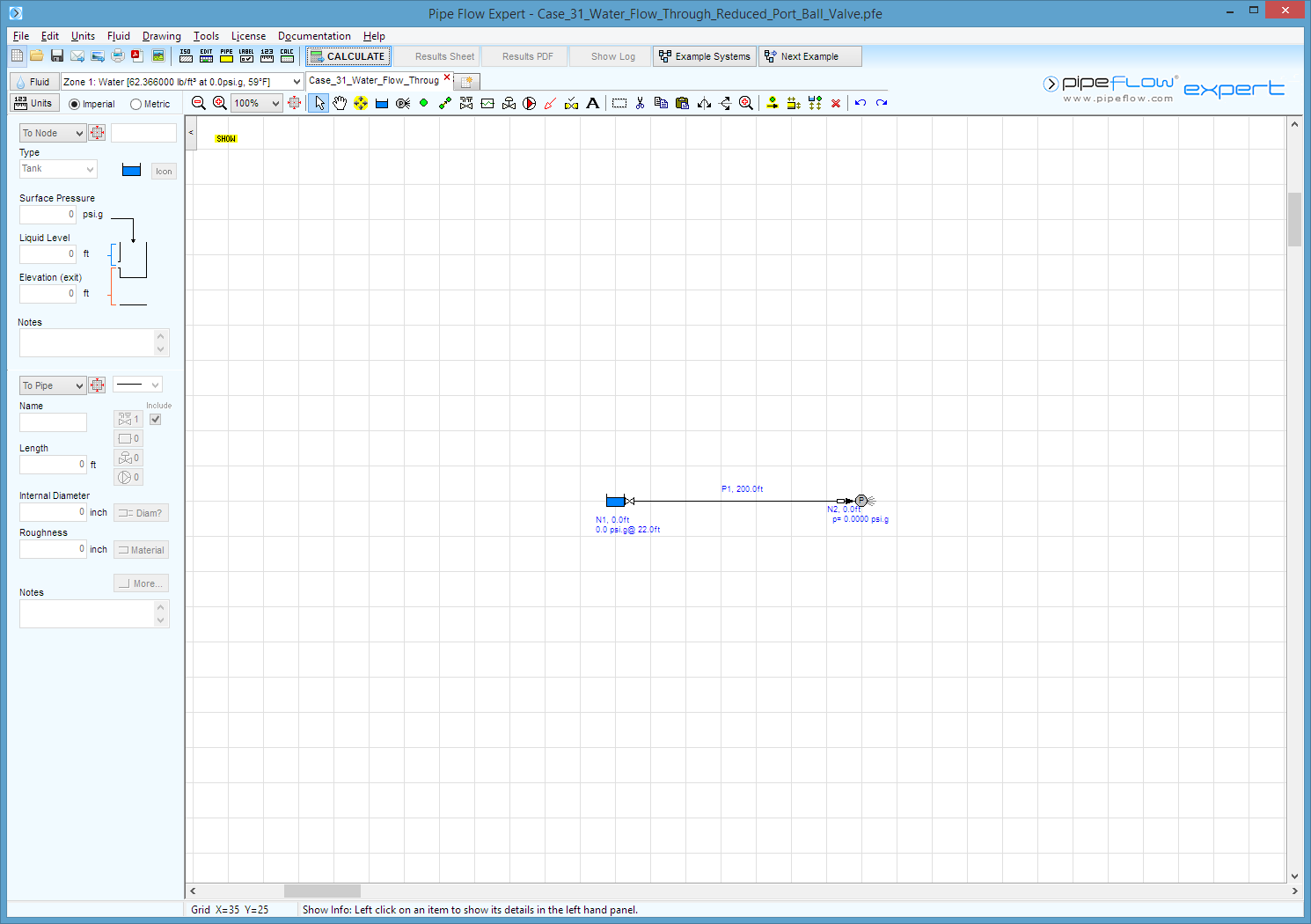

Pipe Flow Expert File: Case_31_Water_Flow_Through_Reduced_Port_Ball_Valve.pfe

Problem Description:

A 200 foot long 3” diameter steel pipe (schedule 40) carries water at 60°F.

The head of fluid in the supply tank is 22 ft.

The piping includes 6 standard 90° elbows and a flanged ball valve with a conical seat.

Find the fluid velocity in the pipe and the rate of discharge.

Fluid Data: Water at 60°F

Result Comparison:

|

Data Item |

Published data |

Pipe Flow Expert |

|

Fluid Velocity in Pipe (ft/s) |

8.5 |

8.307 |

|

Rate of Discharge (gpm ) |

196 |

191.40 |

|

Reynolds Number |

Not calculated |

173201 |

|

Friction factor |

0.018 (assumed) |

0.0195 |

Commentary:

The published data and the calculated results differ by around 2.4%.

The published data uses an assumed friction factor of 0.018 for a 3” diameter steel pipe.

As a final check in the published data the friction factor is read as from a chart as less than 0.02.

If the chart is read accurately the friction factor is 0.0195.

However the text concludes that difference in the assumed friction factor and the friction factor

read from the chart is small enough so as not to require any further correction.

A new valve fitting was created in Pipe Flow Expert to model the flanged ball valve as this item is not included in the database of standard valves and fittings.