Case 32: SAE 10 Lube Oil - Laminar Flow in Valves

Reference: Flow of Fluids – Technical Paper No 410, 1988, Crane Co. Page 4-4, Example 4-7

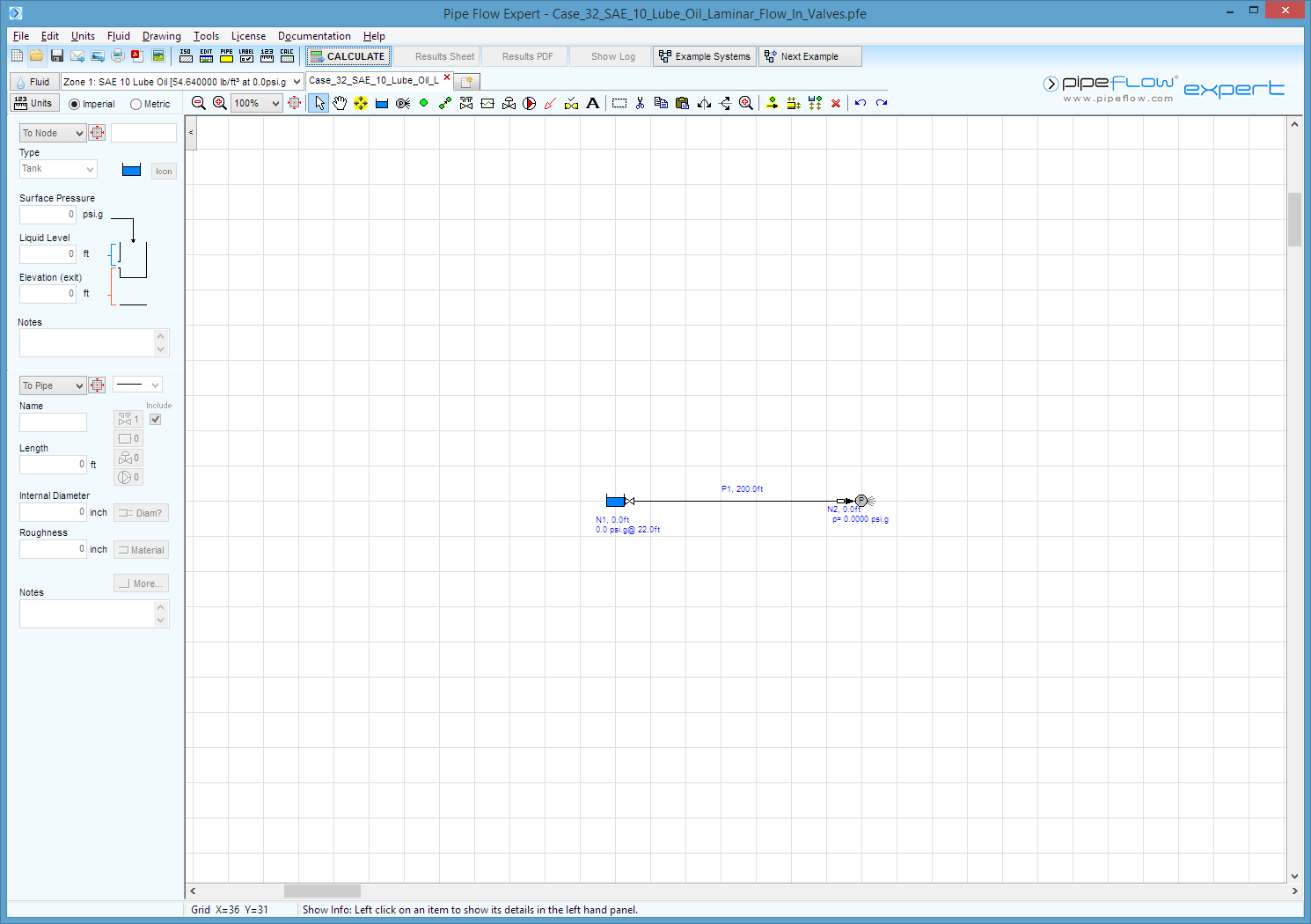

Pipe Flow Expert File: Case_32_SAE_10_Lube_Oil_Laminar_Flow_In_Valves.pfe

Problem Description:

A 200 foot long 3” diameter steel pipe (schedule 40) carries SAE 10 Lube Oil at 60°F.

The head of fluid in the supply tank is 22 ft.

The piping includes 6 standard 90° elbows and a flanged ball valve with a conical seat.

Find the fluid velocity in the pipe and the rate of discharge.

Fluid Data: SAE 10 Lube Oil at 60°F

Result Comparison:

|

Data Item |

Published data |

Pipe Flow Expert |

|

Fluid Velocity in Pipe (ft/s) |

5.13 |

5.271 |

|

Rate of Discharge (gpm ) |

118 |

121.46 |

|

Reynolds Number |

1040 (1st Iteration) |

1096 |

|

Friction factor |

0.062 (1st Iteration) |

0.05840 |

Commentary:

The published data and the calculated results differ by around 3%.

The published text acknowledges that the problem has two unknowns and requires a trial and error solution.

The published data results are for the first initial assumption of velocity.

Pipe Flow Expert performs numerous iterations to find a solution which is accurate to within 0.0004 ft head

pressure loss.

A new valve fitting was created in Pipe Flow Expert to model the flanged ball valve as this item is not included in the database of standard valves and fittings.