Case 51: Water - Sharp-edged Orifice Loss Coefficient in a Straight Pipe

Reference: Pipe Flow – A Practical and Comprehensive Guide, 2012, Publisher Wiley, Donald C. Rennels, Hobart M. Hudson, Chapter 13, Page 140

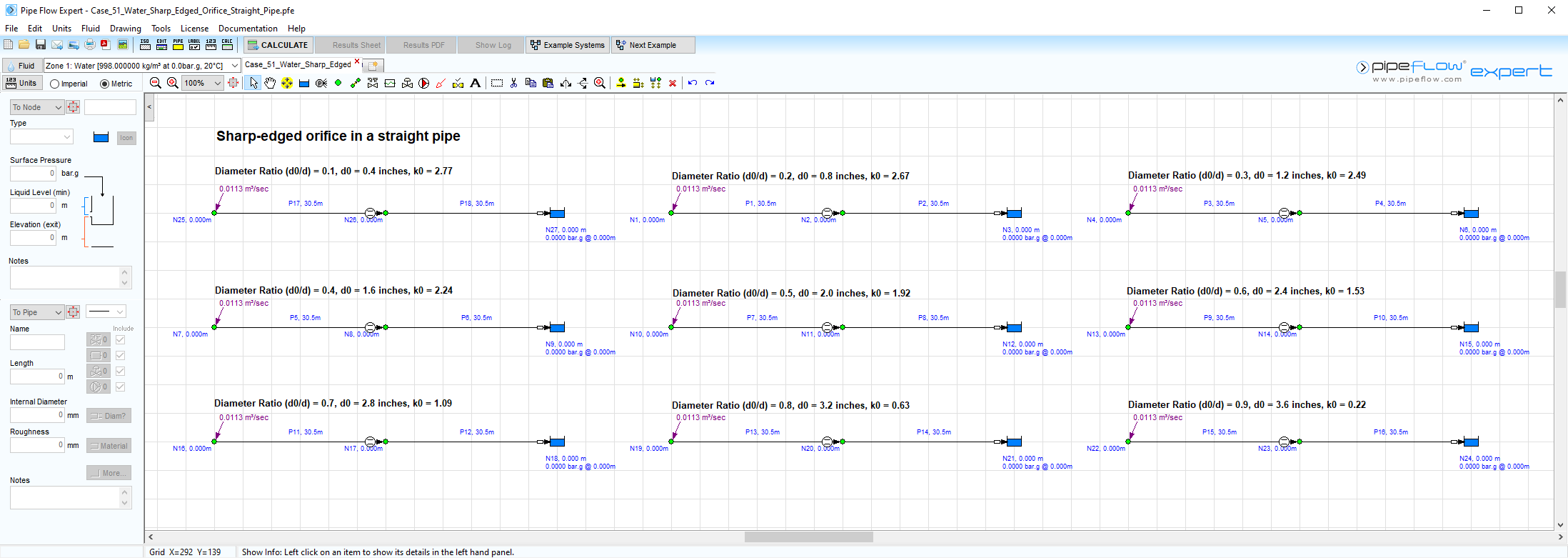

Pipe Flow Expert File: Case_51_Water_Sharp_Edged_Orifice_Straight_Pipe.pfe

Problem Description:

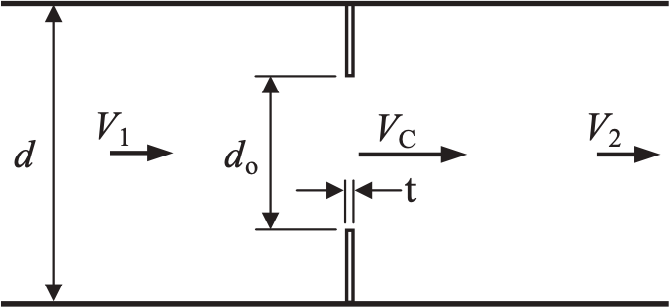

A straight pipe contains a sharp-edged single-hole orifice.

Use different diameter ratios ( = d0/d) to calculate the loss coefficient (k0) of the orifice, where d0 is orifice diameter and d is the pipe diameter.

The published data uses different calculation methods:

Rennels / Hudson, Equation 13.3, ASME Fluid Meters, and Alvi et al.

Pipe Flow Expert Parameters:

Fluid Data: Water at, 68 °F

Pipe Data: Internal diameter 4 inches, wall thickness 0.237 inches, roughness 1881 micro-inches

Nine systems, each with an inflow demand of 0.4 ft3/sec, were used to model orifice diameter to pipe diameter ratios ( = d0/d) from 0.1 through to 0.9.

Result Comparison:

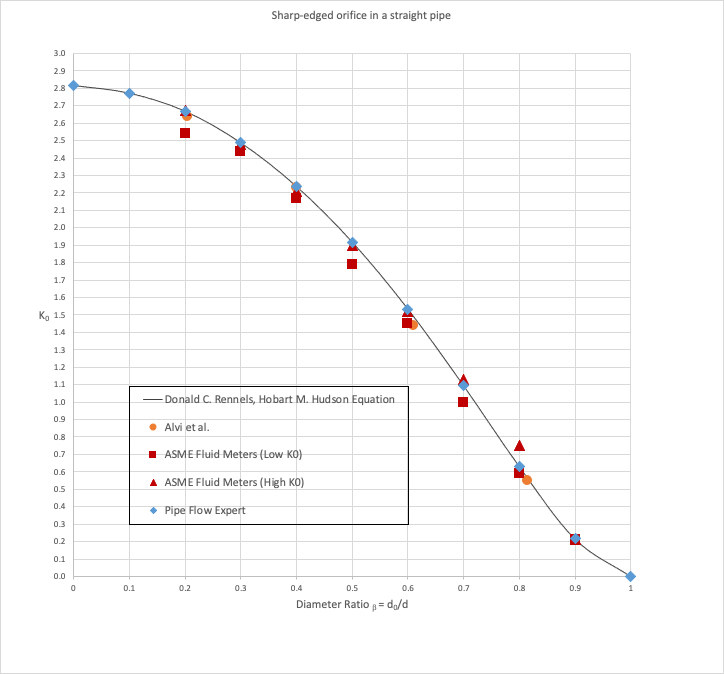

Pipe Flow Expert Calculated Results and Published Graph Readings of Orifice Loss Coefficient (k0):

|

Orifice Diameter / Pipe Diameter (d0/d) |

ASME Fluid Meters (High k0) |

ASME Fluid Meters (Low k0) |

Alvi et al. (k0) |

Donald C. Rennels, Hobart M. Hudson (k0) |

Pipe Flow Expert (k0) |

|

0.1 |

- |

- |

- |

2.77 |

2.77 |

|

0.2 |

2.67 |

2.54 |

- |

2.67 |

2.67 |

|

0.205 |

- |

- |

2.64 |

- |

|

|

0.3 |

2.48 |

2.44 |

- |

2.49 |

2.49 |

|

0.4 |

2.21 |

2.17 |

2.23 |

2.24 |

2.24 |

|

0.5 |

1.9 |

1.79 |

- |

1.92 |

1.92 |

|

0.6 |

1.52 |

1.45 |

- |

1.53 |

1.53 |

|

0.61 |

- |

- |

1.44 |

|

|

|

0.7 |

1.13 |

1 |

- |

1.09 |

1.09 |

|

0.8 |

0.749 |

0.59 |

- |

0.63 |

0.63 |

|

0.815 |

- |

- |

0.55 |

|

|

|

0.9 |

0.21 |

0.21 |

- |

0.22 |

0.22 |

Graphical Comparison of Results:

Commentary:

The published k0 loss coefficients compare well with the calculated results.

Note: Head Loss in m fluid = (k0 * v2) / 2g

- where v = fluid velocity in m/s at the entrance to the orifice, g = acceleration due to gravity in m/s2

- k0 is not the same as a standard k value (which is used in formulas where v = velocity in the pipe)