Case 21: Air Pressure Drop in Steel Pipe

Reference: Piping Calculations Manual, 2005, McGraw-Hill, E. Shashi Menon, Chapter 5, page 265 Example 5.8

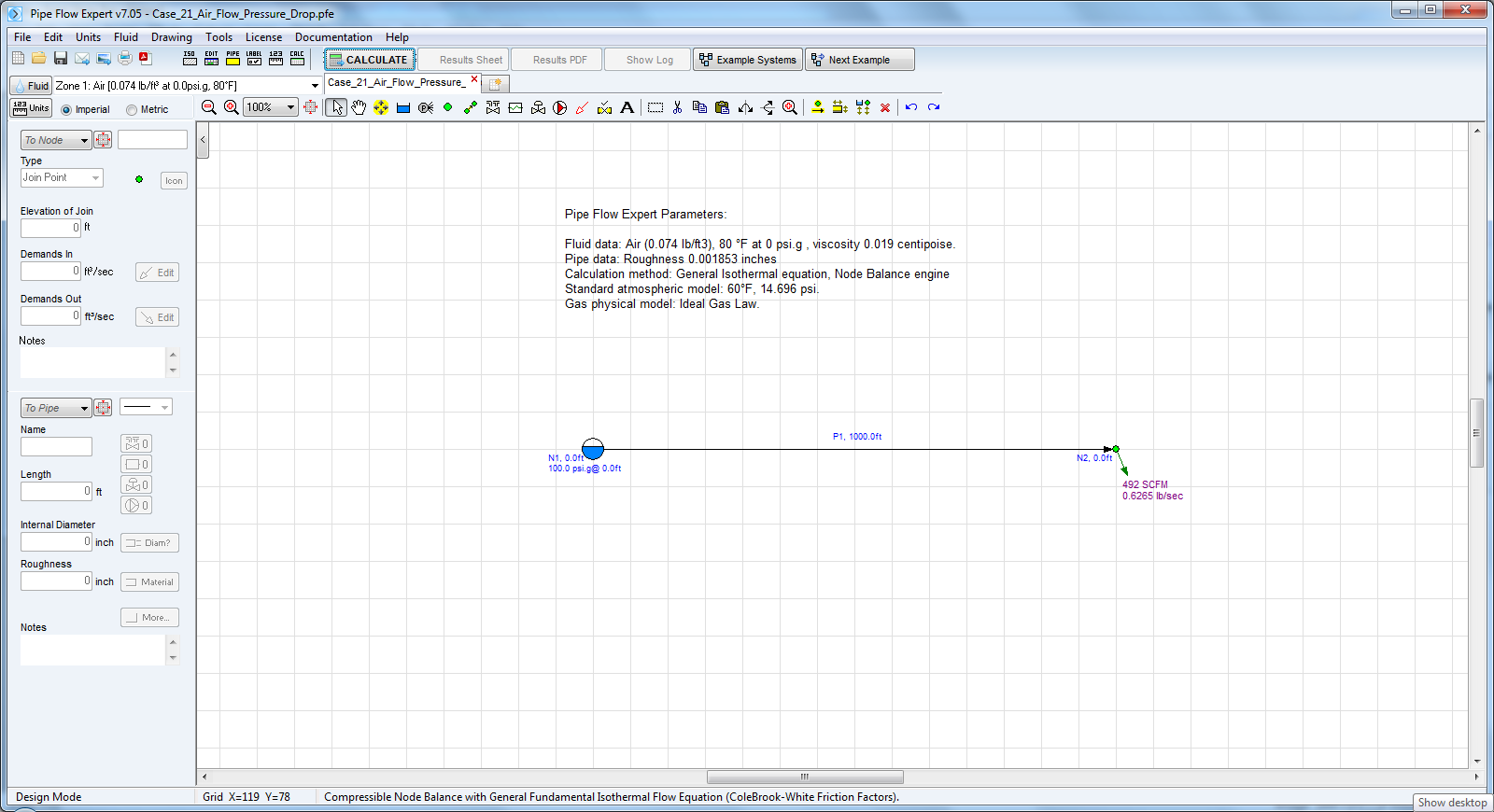

Pipe Flow Expert File: Case_21_Air_Flow_Pressure_Drop.pfe

Problem Description:

Air flows at 50 ft/s in a 2” inside diameter pipe at 80°F, at an initial pressure of 100 psi.g.

If the pipe is horizontal and 1000 ft long, calculate the pressure drop if the flow is isothermal.

Use a friction factor of 0.02.

The calculation method used for the published data was the General Isothermal Flow Equation.

Fluid Data:

|

Air at 80 °F, 0.0 bar.g, density 0.0736 lb/ft3, viscosity 0.0185 centipoise. |

|

Pipe Flow Expert will automatically calculate for compression of the gas to the 100 psi.g condition. |

|

The fluid data must however be defined at the required temperature. |

Pipe Data: Roughness 0.001853 inches (pipe material Steel (ANSI) schedule 40).

Calculation Method: General Isothermal Flow equation, Node Adjust Method.

Standard Atmospheric Model: 60°F, 14.696 psi.a

Gas Physical Model: Ideal gas Law.

Result Comparison:

|

Data Item |

Published data |

Pipe Flow Expert |

|

Outlet Pressure (psi.a) |

94.18 |

94.1782 |

|

Pressure drop (psi) |

20.52 |

20.5178 |

Commentary:

The published data and the calculated results compare well.

The normal pipe roughness for mild steel pipe is 0.001811 inches, however this was adjusted to 0.001853 inches to give a friction factor of 0.02 as assumed in the published text.

Although the fluid data is defined for 80°F and 0.0 bar.g, Pipe Flow Expert’s compressible flow engine automatically accounts for and calculates for compression of the air down to the 100 psi.g starting condition.