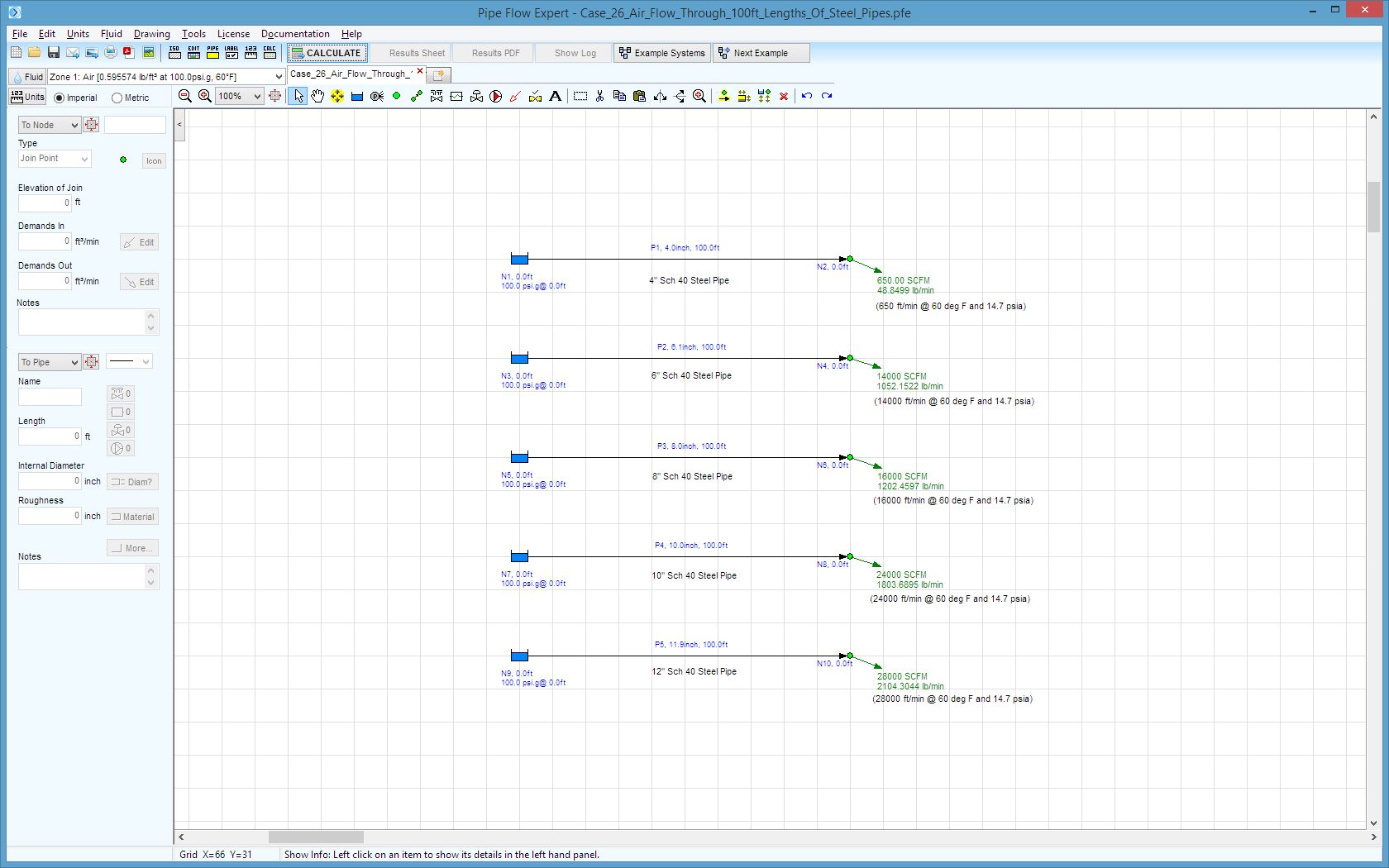

Case 26: Air – Flow Through 100ft Lengths of Steel Pipes

Reference: Flow of Fluids – Technical Paper No 410, 1988, Crane Co. Appendix B-15.

Pipe Flow Expert File: Case_38_Air_Flow_Through_100ft_Lengths_Of_Steel_Pipes.pfe

Problem Description:

Compressed air at 100 psi gauge and 60°F flows through 100 feet long schedule 40 steel pipes.

Find the pressure drop in each of the pipes.

Fluid Data: Air at 100 psi gauge and 60°F, density 0.595574 lb/ft3, viscosity 0.018095 centipoise.

Pipe Data: Internal diameters of standard Schedule 40 Steel pipe, various sizes. Roughness 0.001811 inches.

Calculation Method: General Isothermal Flow equation, Node Adjust Method.

Standard Atmospheric Model: 60 °F, 14.696 psi absolute

Gas Physical Model: Ideal Gas Law

Result Comparison:

|

Pipe Details |

Free Air ft³/min |

Compressed Flow ft³/min |

Published Pressure Drop (psi) |

Pipe Flow Expert Pressure Drop (psi) |

|

4.0” Diameter Schedule 40 Steel Pipe, 100 ft long |

650 |

83.3 |

0.086 |

0.0832 |

|

6.0” Diameter Schedule 40 Steel Pipe, 100 ft long |

14000 |

1794 |

4.21 |

4.2228 |

|

8.0” Diameter Schedule 40 Steel Pipe, 100 ft long |

16000 |

2051 |

1.33 |

1.3121 |

|

10.0” Diameter Schedule 40 Steel Pipe, 100 ft long |

24000 |

3076 |

0.918 |

0.9029 |

|

12.0” Diameter Schedule 40 Steel Pipe, 100 ft long |

28000 |

3588 |

0.505 |

0.4957 |

Commentary:

The published data and the calculated results compare well. The density of Air at 100 psi.g and 60°F used in the calculation of the published results was not specified, and the results were based on a non-compressible calculation since the pressure drop was small.

Pipe Flow Expert’s gas helper calculated the density of the Air at 0.595574 lb/ft3 and used a compressible flow equation to calculate the results.