Case 41: Carbon Dioxide – Flow Through a Pipe

Reference: 2500 Solved Problems in Fluid Mechanics and Hydraulics, 1989, McGraw-Hill, Jack B. Evett, Ph. D., Cheng Liu, M.S., Page 483, Example problem 16.78

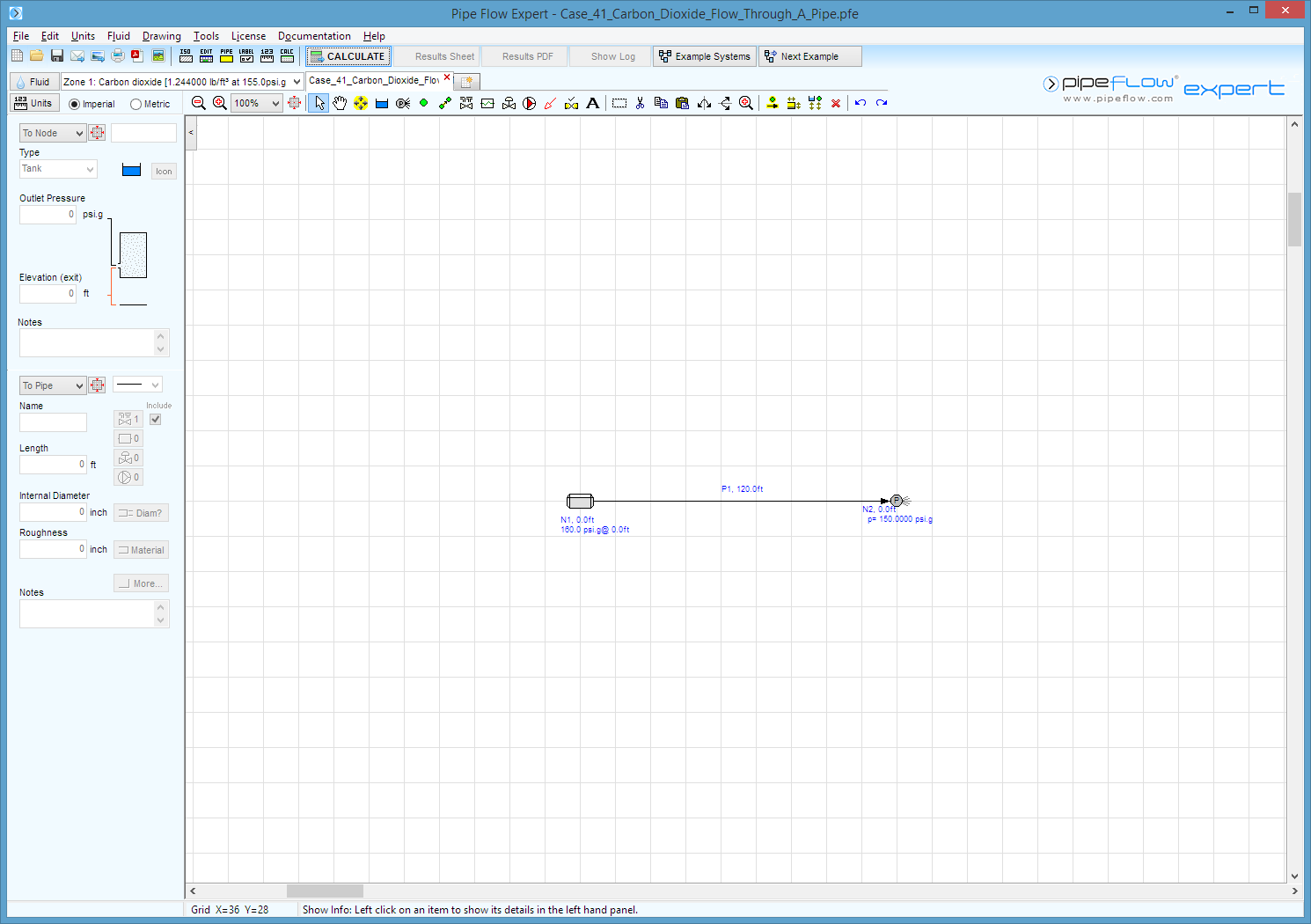

Pipe Flow Expert File: Case_41_Carbon_Dioxide_Flow_Through_A_Pipe.pfe

Problem Description:

Carbon Dioxide at temperature of 100°F flows through a pipe with 6” internal diameter.

The pipe internal roughness is 0.002 ft (0.024”).

The flow is isothermal.

The pressure at the start of a 120 ft long horizontal pipe section is 160 psig the pressure at the end of the section is 150 psig.

Calculate the weight flow rate of the air.

Note: This case is solved here using Pipe Flow Expert’s non-compressible calculation engine. See the commentary below for more details.

This case has also been solved using Pipe Flow Expert’s compressible calculation engine and the results are reported in the separate Compressible Results Verification document (Case 27).

Fluid Data: Carbon Dioxide at 100°F

Result Comparison:

|

Data Item |

Published data |

Pipe Flow Expert |

|

Weight of Flow (lb/sec) |

25.3 |

25.5343 |

|

Reynolds Number |

5000000 |

6242864 |

|

Friction Factor |

0.0285 |

0.0284 |

Commentary:

The published data and the calculated results compare well.

The published text assumes an initial Reynolds Number greater than 1000000 and a friction factor of 0.0285 which is used to estimate the weight of flow as 25.3 lb/sec.

The weight of flow is then used to recalculate the Reynolds Number as 5000000.

The new Reynolds Number is greater than the initial assumption of the Reynolds Number and is taken as confirmation of the previously calculated weight of flow.

The Pipe Flow Expert program uses the Colebrook-White equation to determine friction factors.

The Colebrook-White equation is usually considered to be more accurate than a value read from a Moody Chart.

Normally Pipe Flow Expert would be used with the Compressible Flow calculation engine to analyze this system.