Case 53: Water - Thick-edged Orifice Loss Coefficient in a Straight Pipe

Reference: Pipe Flow – A Practical and Comprehensive Guide, 2012, Publisher Wiley, Donald C. Rennels, Hobart M. Hudson, Chapter 13, Page 146

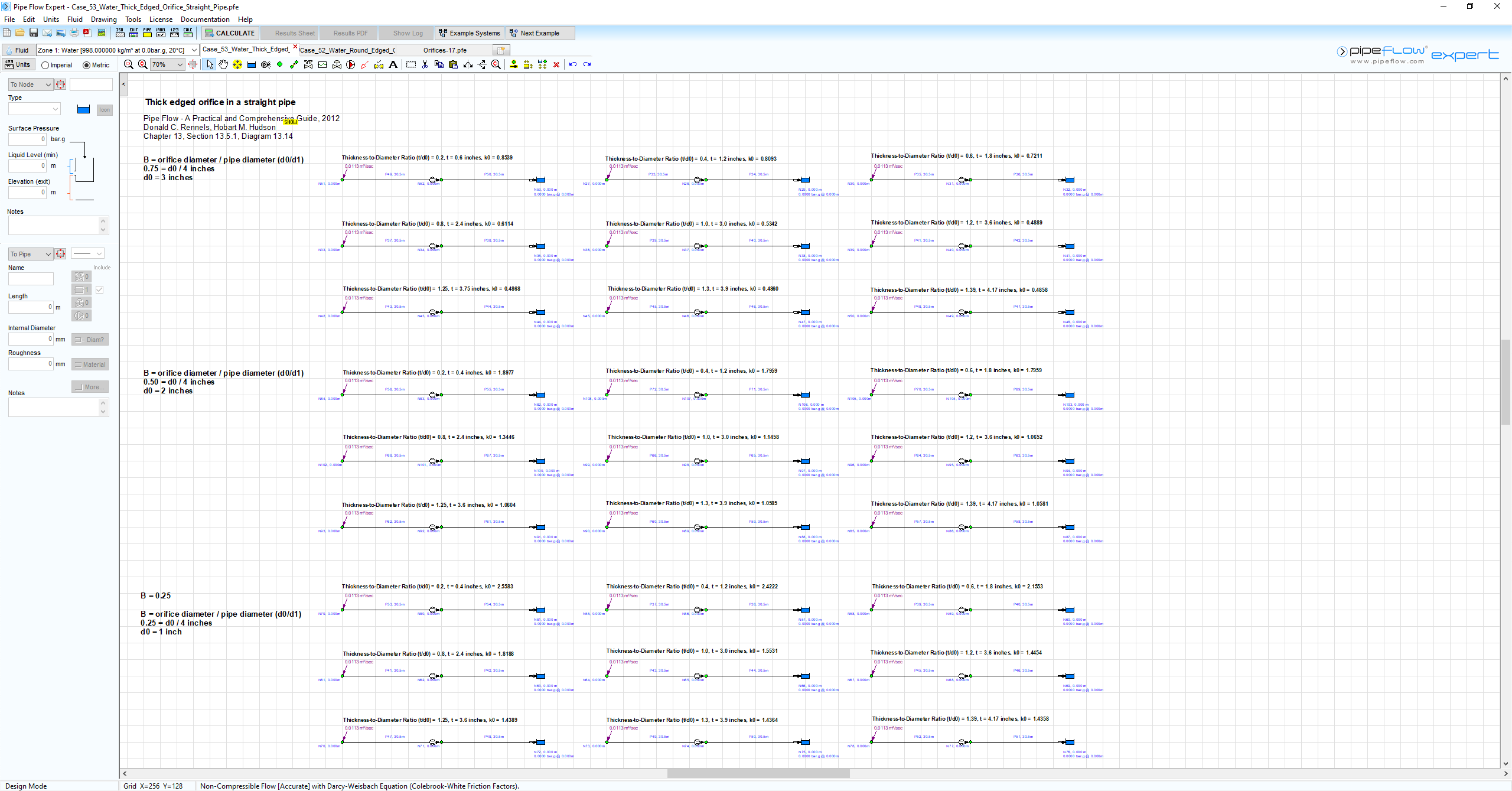

Pipe Flow Expert File: Case_53_Water_Thick_Edged_Orifice_Straight_Pipe.pfe

Problem Description:

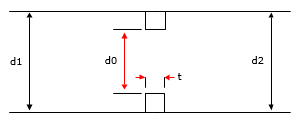

A straight pipe contains a thick-edged single-hole orifice. Find the k0 loss coefficient for the orifice with thickness specified as a ratio against the diameter of the orifice (t/d0).

Use different orifice thickness to orifice diameter ratios (t/d0) to compare the calculated orifice loss coefficient (k0) across a range of different orifice diameter to pipe diameter ratios.

The published data uses different calculation methods for comparison:

Donald C. Rennels, Hobart M. Hudson, Equation 13.13, James A.J., Sanderson E. W.

Pipe Flow Expert Parameters:

Fluid Data: Water at, 68 °F

Pipe Data: Internal diameter 4 inches, wall thickness 0.237 inches, roughness 1881 micro-inches

The following 27 systems, each with an inflow demand of 0.4 ft3/sec, were used to model orifices with a

thickness / diameter ratio (t/d0) ranging from 0.2 through to 2.0.

|

System # |

= d0/d1 (Orifice Diameter / Pipe Diameter) |

|

1 – 9 |

0.75 |

|

10 – 18 |

0.50 |

|

19 – 27 |

0.25 |

Result Comparison:

Pipe Flow Expert Calculated Results and Published Graph Readings of Orifice Loss Coefficient (k0):

|

Orifice Thickness / Orifice Diameter (t/d0) |

Orifice Diameter / Pipe Diameter ( = d0/d1) |

Donald C. Rennels, Hobart M. Hudson (k0) |

James |

Sanderson ( = 0.252) (k0) |

Pipe Flow Expert (k0) |

|

0.2 |

0.75 |

0.8539 |

- |

- |

0.8539 |

|

0.4 |

0.75 |

0.8093 |

- |

- |

0.8093 |

|

0.6 |

0.75 |

0.7211 |

- |

- |

0.7211 |

|

0.8 |

0.75 |

0.6114 |

- |

- |

0.6114 |

|

1.0 |

0.75 |

0.5243 |

- |

- |

0.5243 |

|

1.2 |

0.75 |

0.4889 |

- |

- |

0.4889 |

|

1.25 |

0.75 |

0.4868 |

- |

- |

0.4868 |

|

1.3 |

0.75 |

0.4860 |

- |

- |

0.4860 |

|

1.39 |

0.75 |

0.4858 |

- |

- |

0.4858 |

|

2 |

0.75 |

0.4858 |

- |

- |

0.4858 |

|

0.2 |

0.5 |

1.8977 |

- |

- |

1.8977 |

|

0.4 |

0.5 |

1.7959 |

- |

- |

1.7959 |

|

0.6 |

0.5 |

1.5947 |

- |

- |

1.5947 |

|

0.8 |

0.5 |

1.3446 |

- |

- |

1.3446 |

|

1.0 |

0.5 |

1.1458 |

- |

- |

1.1458 |

|

1.2 |

0.5 |

1.0652 |

- |

- |

1.0652 |

|

1.25 |

0.5 |

1.0604 |

- |

- |

1.0604 |

|

1.3 |

0.5 |

1.0585 |

- |

- |

1.0585 |

|

1.39 |

0.5 |

1.0581 |

- |

- |

1.0581 |

|

2 |

0.5 |

1.0581 |

- |

- |

1.0581 |

|

0.132 |

0.25 |

- |

- |

2.52 |

- |

|

0.2 |

0.25 |

2.6000 |

- |

- |

2.6000 |

|

0.245 |

0.25 |

- |

- |

2.74 |

- |

|

0.4 |

0.25 |

2.5583 |

- |

- |

2.5583 |

|

0.5 |

0.25 |

- |

2.5 |

2.28 |

- |

|

0.6 |

0.25 |

2.4222 |

- |

- |

2.4222 |

|

0.75 |

0.25 |

- |

1.87 |

- |

- |

|

0.8 |

0.25 |

2.1553 |

- |

- |

2.1553 |

|

0.995 |

0.25 |

- |

1.61 |

|

- |

|

1.0 |

0.25 |

1.8188 |

- |

1.7 |

1.8188 |

|

1.2 |

0.25 |

1.5531 |

- |

- |

1.5531 |

|

1.25 |

0.25 |

1.4454 |

- |

- |

1.4454 |

|

1.3 |

0.25 |

1.4389 |

- |

- |

1.4389 |

|

1.39 |

0.25 |

1.4364 |

- |

- |

1.4364 |

|

1.4 |

0.25 |

- |

- |

1.62 |

- |

|

1.6 |

0.25 |

- |

- |

1.56 |

- |

|

1.89 |

0.25 |

- |

1.55 |

1.58 |

- |

|

2 |

0.25 |

1.4358 |

- |

- |

1.4358 |

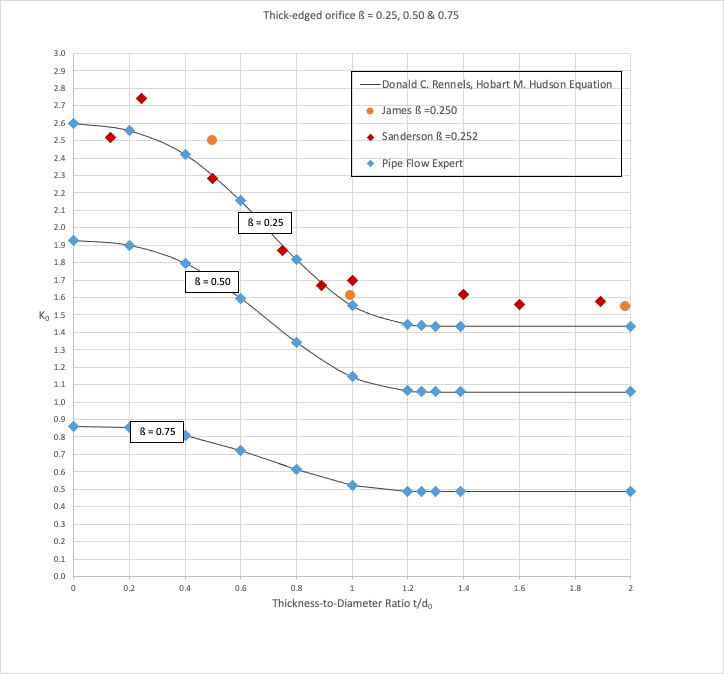

Graphical Comparison of Results:

Commentary:

The published k0 loss coefficients compare well with the calculated results.

Note: Head Loss in m fluid = (k0 * v2) / 2g

- where v = fluid velocity in m/s at the entrance to the orifice, g = acceleration due to gravity in m/s2

- k0 is not the same as a standard k value (which is used in formulas where v = velocity in the pipe)